Inconel 625 Tube Manufacturer

Dimension and wall thickness

Pipe diameters

625 Inconel Welded Tubes, ASTM B163 Alloy 625 Seamless Tubing, Alloy 625 ERW Tubes Supplier, 625 Inconel Heat exchanger Tube, Inconel 625 Sanitary Tube, ASTM B516 Inconel 625 Welded Tubing, Inconel 625 Electropolish Tube, 625 Inconel BRIGHT ANNEALED Tube, 625 Inconel Tubing, GOST ХН75МБТЮ Tubes, 625 Alloy Polish Tubing, Inconel NCF 625 Tubes, Alloy 625 Tubing, Inconel Tube, Inconel Alloy 625 Tubes Suppliers and Exporters in Mumbai, India.

Inconel 625 Decorative Tube, Inconel 625 Welded Tubes Stockist, Stockholder of ASTM B163 Inconel 625 Tube, Inconel Alloy 625 Tubing, Dealer of ASTM B516 Inconel 625 Tube, Inconel UNS N06625 Tubing, 625 Inconel Alloy Seamless Tubing, Inconel 625 Cold Rolled Coiled Tube, ASTM B444 Inconel 625 seamless tubing, Inconel 625 Polish Tube, Inconel 625® Tubing, Inconel 625 Welded Tube, Inconel 625 Seamless Tubes, Inconel WERKSTOFF NR. 2.4856 Tubing Manufacturer in India.

Detailed Information

Newzel Steel manufactures and supplies Inconel 625 Tube, With the experience of several years, Newzeel Steel produces Inconel 625 Tubes of high caliber that are reliable for several industries. The Inconel 625 Tube is made from the highest quality of raw materials. We at Newzel Steel have a team of experienced workers who are responsible for the manufacturing of Inconel 625 Tube. The team ensures that all the products manufactured to meet the requirements and necessities of the customers. Newzel Steel houses a highly equipped manufacturing facility. It allows us to produce these Inconel 625 Tubes in different sizes and dimensions.

Alloy 625 is a nickel-chromium alloy used for its high strength, excellent fabricability, and outstanding corrosion resistance. Service temperatures can range from cryogenic to 980°C (1800°F). Alloy 625 strength is derived from the solid solution strengthening effect of molybdenum and niobium on its nickel-chromium matrix. It is nonmagnetic, exhibits high fatigue strength, and will maintain its performance and mechanical properties across a very wide temperature range (from cryogenic to 2,000°F/1,093°C). The UNS N06625 alloy or as referred to as Inconel 625 Tubing material is produced in 2 grades. The Inconel 625 Grade 1 Seamless Tubing is furnished in an annealed condition. On the other hand, Inconel 625 Grade 2 Round Tubing, as directed by the ASTM B444 specification is to be furnished in a solution annealed condition. Inconel 625 Pipe is a nickel-chromium superalloy pipe that is made up of 58% nickel, 20% chromium, carbon, manganese, silicon, iron, sulfur, aluminum, and titanium in composition. The pipes are highly corrosion resistant. Navstar Steel is a leading manufacturer and supplier of the Inconel 625 Pipe and tubes. The material has 517MPa minimum yield strength and 930MPa minimum tensile strength. Inconel 625 is one of seven corrosion-resistant alloys in our special metals range. Other properties of alloy 625 include high creep-rupture strength and its addition of niobium. Niobium acts with molybdenum content to stiffen the alloy matrix. Magellan Metals provides Inconel 625® tube in standard sizes up to 3” O.D. We offer both welded and seamless Inconel tubes in both aerospace (AMS 5581) and commercial specifications (ASTM B444). Our Inconel 625® tube also meets numerous other national and international standards. The aerospace industry embraces Inconel® Alloy 625 tubing for its high tensile, creep, and rupture strength, fatigue and thermal-fatigue strength, oxidation resistance, and excellent weldability, making it a useful material for engine exhaust systems, fuel, and hydraulic line tubing, and heat exchanger tubing. The Inconel 625 Electropolish Tube has the ability to retains its excellent ductility properties as well as toughness properties even at low working temperatures. The two crucial properties of the alloy, which make them stand out according to Inconel 625 tube suppliers are its resistance to oxidation as well as its resistance to scaling at very high temperatures. These two properties of the 625 Inconel Heat exchanger Tube make the alloy superior in comparison to other alloys, even those metals which have been produced for high temperatures and varying heating as well as cooling conditions. Newzel Steel is a distributor of Nickel Alloy 625 and Inconel 625 in the pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon, wire, and extruded section. The mills we work with to supply customers with alloy 625 meet or exceed many of the leading industry standards including those from ASTM, ASME, SAE, AMS, ISO, DIN, EN, and BS.

Before supplying these Inconel 625 Tubes to our clients, they are tested in terms of quality by our quality controllers such as hardness, micro and, macro tests. Because of the wide scope of widths and thicknesses and the assortment of tempers delivered in our Inconel 625 Tube and cut lengths, no levelness resiliences have been set up for cold moved hardened steel. Evenness on temper abounded in these Inconel 625 Tubes can’t be ensured. This Inconel 625 Tube Cap is a universally useful grade often supplied in the solidified, yet machinable condition, for applications where high strength and moderate warmth and erosion obstruction are required.

Cities We Delivered

New York City, Los Angeles, Chicago, Houston, Phoenix, Philadelphia, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, Fort Worth, Columbus, Charlotte, San Francisco, Indianapolis, Seattle, Denver, Washington, Boston, El Paso, Nashville, Detroit, Oklahoma City, Portland, Las Vegas, Memphis, Louisville, Baltimore, Milwaukee, Albuquerque, Tucson, Fresno, Mesa, Sacramento, Atlanta, Kansas City, Colorado Springs, Omaha, Raleigh, Miami, Long Beach, Virginia Beach, Oakland, Minneapolis, Tulsa, Tampa, Arlington, New Orleans, Wichita, Bakersfield, Cleveland, Aurora, Anaheim, Honolulu, Santa Ana, Riverside, Corpus Christi, Lexington, Henderson, Stockton, Saint Paul, Cincinnati, St. Louis, Pittsburgh, Greensboro, Lincoln, Anchorage, Plano, Orlando, Irvine, Newark, Durham, Chula Vista, Toledo, Fort Wayne, St. Petersburg, Laredo, Jersey City, Chandler, Madison, Lubbock, Scottsdale, Reno, Buffalo, Gilbert, Glendale, North Las Vegas, Winston-Salem, Chesapeake, Norfolk, Fremont, Garland, Irving, Hialeah, Richmond, Boise, Spokane, Baton Rouge, Tacoma, San Bernardino, Modesto, Fontana, Des Moines, Moreno Valley, Santa Clarita, Fayetteville, Birmingham, Oxnard, Rochester, Port St. Lucie, Grand Rapids, Huntsville, Salt Lake City, Frisco, Yonkers, Amarillo, Glendale, Huntington Beach, McKinney, Montgomery, Augusta, Aurora, Akron, Little Rock, Tempe, Columbus, Overland Park, Grand Prairie, Tallahassee, Cape Coral, Mobile, Knoxville, Shreveport, Worcester, Ontario, Vancouver, Sioux Falls, Chattanooga, Brownsville, Fort Lauderdale, Providence, Newport News, Rancho Cucamonga, Santa Rosa, Peoria, Oceanside, Elk Grove, Salem, Pembroke Pines, Eugene, Garden Grove, Cary, Fort Collins, Corona, Springfield, Jackson, Alexandria, Hayward, Clarksville, Lakewood, Lancaster, Salinas, Palmdale, Hollywood, Springfield, Macon, Kansas City, Sunnyvale, Pomona, Killeen, Escondido, Pasadena, Naperville, Bellevue, Joliet, Murfreesboro, Midland, Rockford, Paterson, Savannah, Bridgeport, Torrance, McAllen, Syracuse, Surprise, Denton, Roseville, Thornton, Miramar, Pasadena, Mesquite, Olathe, Dayton, Carrollton, Waco, Orange, Fullerton, Charleston, West Valley City, Visalia, Hampton, Gainesville, Warren, Coral Springs, Cedar Rapids, Round Rock, Sterling Heights, Kent, Columbia, Santa Clara, New Haven, Stamford, Concord, Elizabeth, Athens, Thousand Oaks, Lafayette, Simi Valley, Topeka, Norman, Fargo, Wilmington, Abilene, Odessa, Columbia, Pearland, Victorville, Hartford, Vallejo, Allentown, Berkeley, Richardson, Arvada, Ann Arbor, Rochester, Cambridge, Sugar Land, Lansing, Evansville, College Station, Fairfield, Clearwater, Beaumont, Independence, Provo, West Jordan, Murrieta, Palm Bay, El Monte, Carlsbad, North Charleston, Temecula, Clovis, Springfield, Meridian, Westminster, Costa Mesa, High Point, Manchester, Pueblo, Lakeland, Pompano Beach, West Palm Beach, Antioch, Everett, Downey, Lowell, Centennial, Elgin, Richmond, Peoria, Broken Arrow, Miami Gardens, Billings, Jurupa Valley, Sandy Springs, Gresham, Lewisville, Hillsboro, Ventura, Greeley, Inglewood, Waterbury, League City, Santa Maria, Tyler, Davie, Lakewood, Daly City, Boulder, Allen, West Covina, Sparks, Wichita Falls, Green Bay, San Mateo, Norwalk, Rialto, Las Cruces, Chico, El Cajon, Burbank, South Bend, Renton, Vista, Davenport, Edinburg, Tuscaloosa, Carmel, Spokane Valley, San Angelo, Vacaville, Clinton, Bend, Woodbridge.

Inconel Alloy 625 Tubes Specifications

|

Specifications |

: |

ASTM B163, B516 / ASME SB163, B516 |

|

Dimensions |

: |

ASTM, ASME and API |

|

Alloy 625 Tubes Size |

: |

6 mm OD x 0.7 mm to 50.8 mm OD x 3 mm thk. |

|

Schedule |

: |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Type |

: |

Seamless / ERW / Welded / Fabricated / LSAW Tubes |

|

Form |

: |

Round, Square, Rectangular, Hydraulic Etc |

|

Length |

: |

Single Random, Double Random & Cut Length. |

|

End |

: |

Plain End, Beveled End, Treaded |

625 Inconel Alloy Tube Chemical Composition

|

Grade |

C |

Mn |

Si |

S |

Cu |

Fe |

Ni |

Cr |

|

Inconel 625 |

0.10max |

0.50 max |

0.50 max |

0.015max |

– |

5.0 max |

58.0 min |

20.0 – 23.0 |

Inconel 625 Tubing Mechanical Properties

|

Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

Inconel 625 |

8.4 g/cm3 |

1350 °C (2460 °F) |

Psi – 1,35,000 , MPa – 930 |

Psi – 75,000 , MPa – 517 |

42.5 % |

Equivalent Grades for 625 Inconel Seamless and Welded Tubes

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

Inconel 625 |

2.4856 |

N06625 |

NCF 625 |

NA 21 |

ХН75МБТЮ |

NC22DNB4M |

NiCr22Mo9Nb |

Inconel 625 Seamless / Welded Tubes Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Alloy 625 Tubing Stock List

|

Alloy |

Product form |

Dimension |

|

ALLOY 625 (61 Ni/22 Cr/9 Mo) |

Tube; seamless, annealed |

4.50 x 0.75 mm |

|

ALLOY 625 (61 Ni/22 Cr/9 Mo) |

Tube; seamless, pickled, annealed |

33.40 x 3.38 mm (1″nb sch40s) |

|

INCONEL 625 (61 Ni/22 Cr/9 Mo) |

Tube; welded, bright solution annealed |

60.33 x 2.77 mm (2″nb sch10s) |

|

INCONEL 625 (61 Ni/22 Cr/9 Mo) |

Tube; seamless, cold drawn, ground, annealed |

60.33 x 3.91 mm (2″nb Sch40s) |

Our Products

Our Latest Blogs

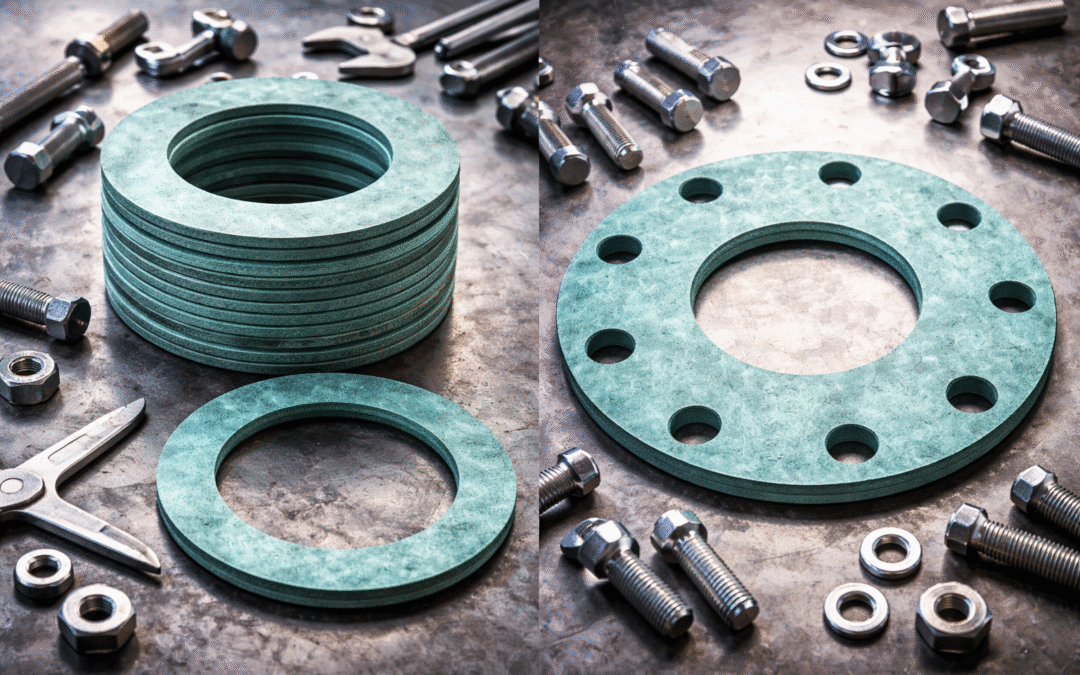

Ring Type Vs Full Face Gaskets

When sealing raised or flat face flanges, there are two gasket shapes available: ring-type and full-face. Each has advantages, so you should choose which is ideal for your application before ordering and installing. First, let's look at the many sorts of flanges where...

Related Products

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 310H Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 316Ti Flanges

- Stainless Steel 317 Flanges

- Stainless Steel 317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 310H Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 316Ti Flanges

- Stainless Steel 317 Flanges

- Stainless Steel 317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 310H Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 316Ti Flanges

- Stainless Steel 317 Flanges

- Stainless Steel 317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 310H Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 316Ti Flanges

- Stainless Steel 317 Flanges

- Stainless Steel 317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 904L Flanges

- Stainless Steel 304 Flanges

- Stainless Steel 304L Flanges

- Stainless Steel 304H Flanges

- Stainless Steel 310 Flanges

- Stainless Steel 310S Flanges

- Stainless Steel 310H Flanges

- Stainless Steel 316 Flanges

- Stainless Steel 316L Flanges

- Stainless Steel 316H Flanges

- Stainless Steel 316Ti Flanges

- Stainless Steel 317 Flanges

- Stainless Steel 317L Flanges

- Stainless Steel 321 Flanges

- Stainless Steel 321H Flanges

- Stainless Steel 347 Flanges

- Stainless Steel 904L Flanges

Before You Go…

would you like a copy of our Handy Guide to leasing an industrial unit straight to your inbox?

Call Us At

Feel free to call on

+91 79774 55576

022-66394744/45

Drop Mail

For Domestic Queries:

jay@newzelindustries.com

For International Queries:

info@newzelindustries.com