by user | Sep 5, 2024 | Blog

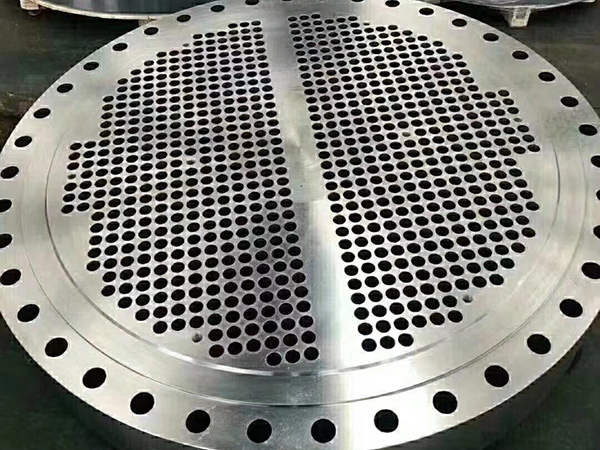

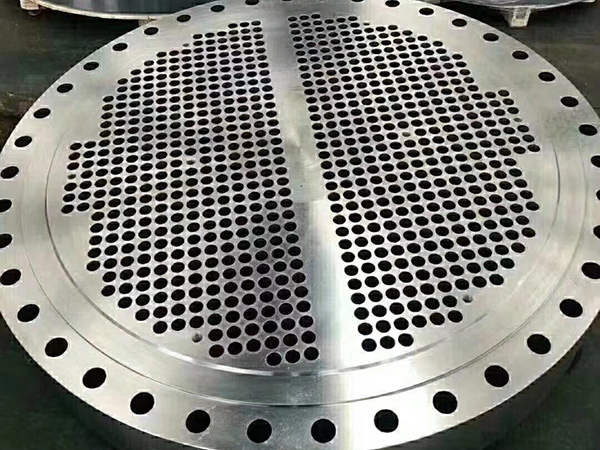

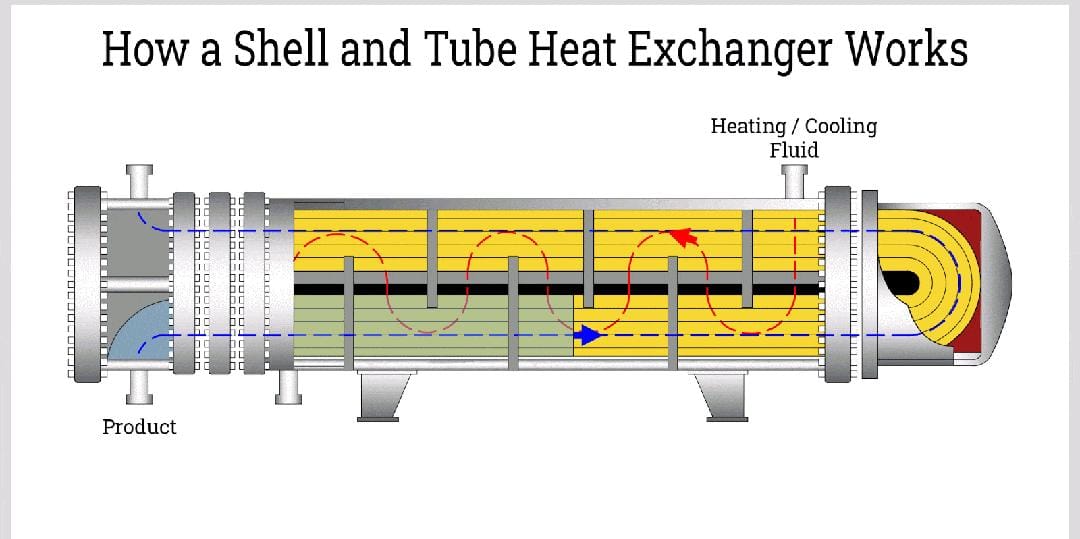

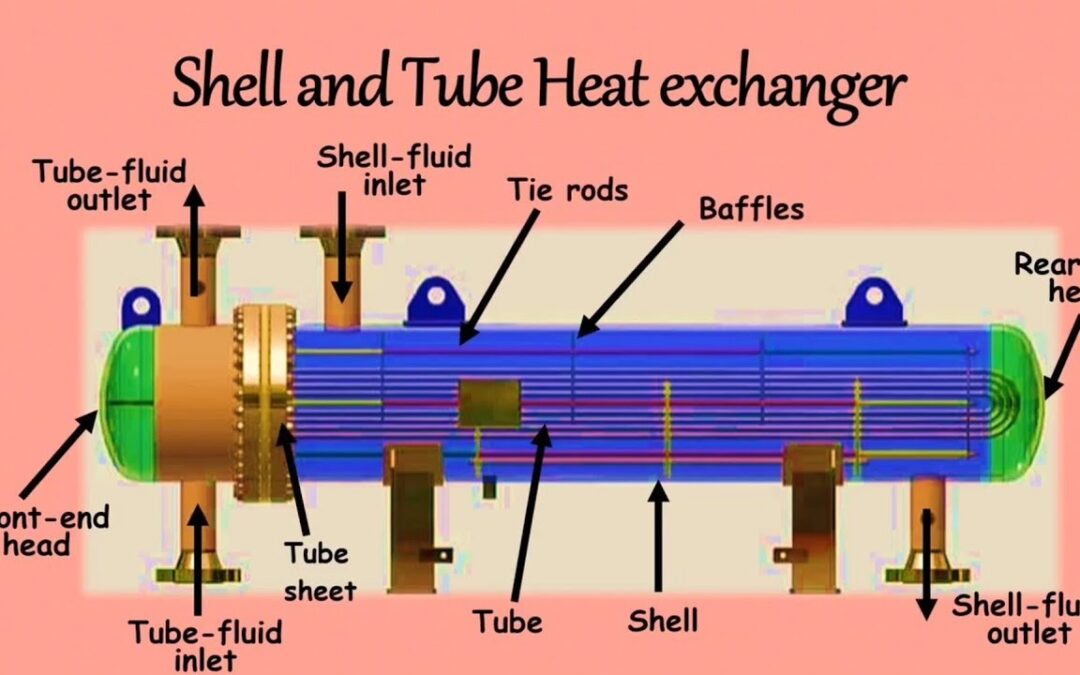

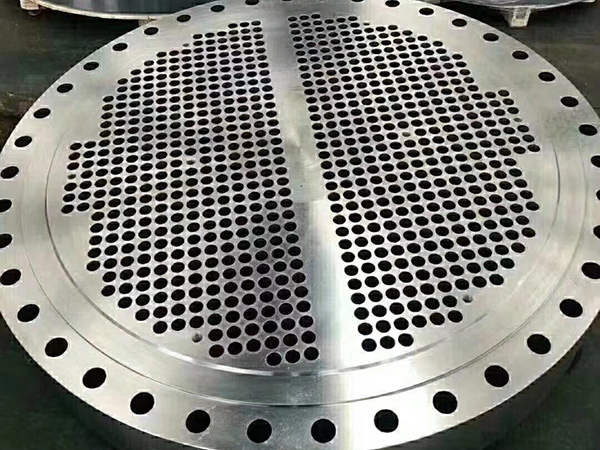

Tube sheets contain perforations punched to accommodate a sequence of tubes within an enclosed tubular pressure vessel. These pressure vessels, also known as shell and tube heat exchangers, are the most frequent type used in oil refineries and big chemical facilities....

by user | Sep 3, 2024 | Blog

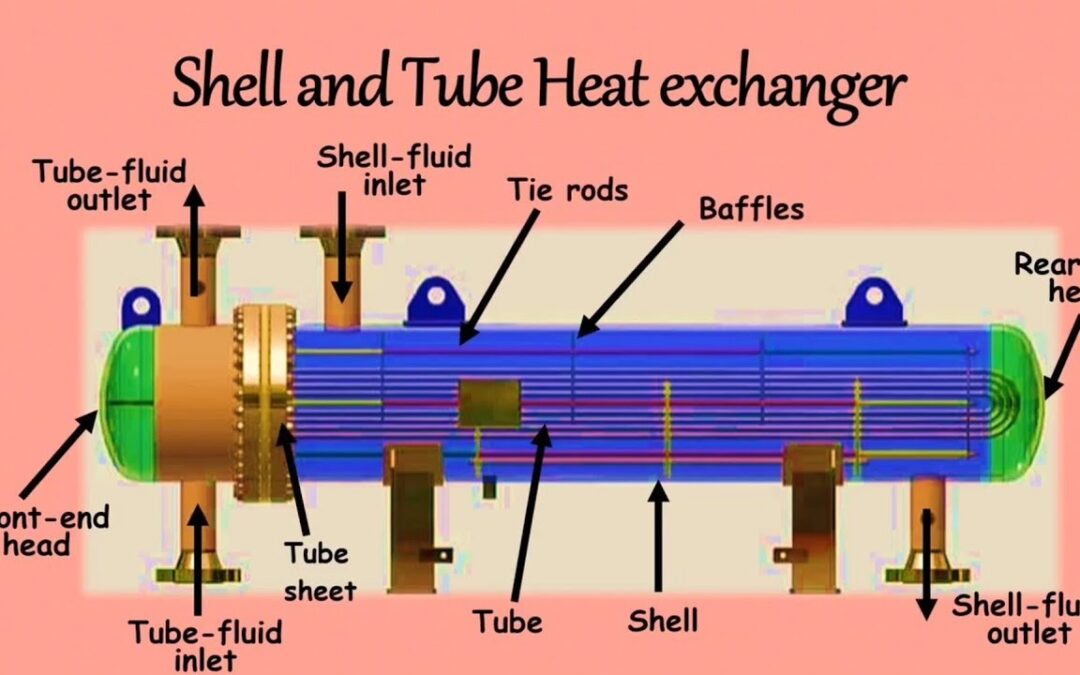

Heat exchanger tubes and tube sheets are two of the most critical parts of a heat exchanger. They are in charge of transporting heat between two fluids, and a good connection between them is required for the heat exchanger to operate well. There are two primary ways...

by user | Sep 1, 2024 | Blog

Tubesheets may not be the most aesthetically pleasing component of your equipment, but they are critical to guaranteeing peak performance. Tubesheets must be properly maintained and cleaned to avoid problems like corrosion, fouling, and lower performance. In this blog...

by user | Aug 24, 2024 | Blog

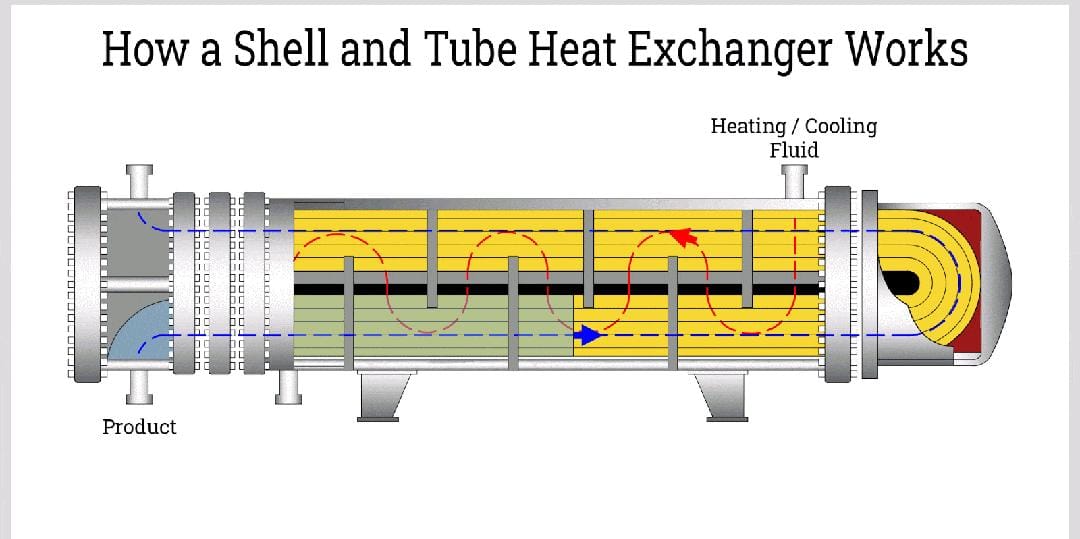

A heat exchanger is a device that transfers heat from two or more fluids (liquids or gasses) without mixing them. It is essential in many sectors because it regulates temperatures, improves energy efficiency, and aids processes that require precise thermal control....

by user | Aug 13, 2024 | Blog

The ASME B31.3 Code specifies the minimum criteria for process pipe design, materials, fabrication, inspection, testing, and commissioning. Your inspection and test plan (ITP) for process piping must meet the ASME B31.3 Code requirements, as explained above. ASME...

by user | Aug 8, 2024 | Blog

Choosing the proper materials for shell and tube heat exchangers is critical for performance and longevity. Here is a simple guide to help you make educated decisions: Key Factors: Corrosion Resistance: Essential to prevent material degradation. Thermal Conductivity:...