Incoloy Products

Introduction

Incoloy Products Australia, Dealers & distributor of Incoloy material and Incoloy Products in Mumbai, India, Incoloy supplier, Incoloy Products, Incoloy price in India.

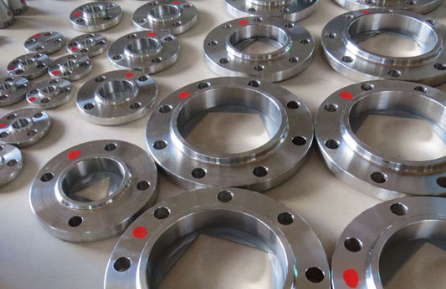

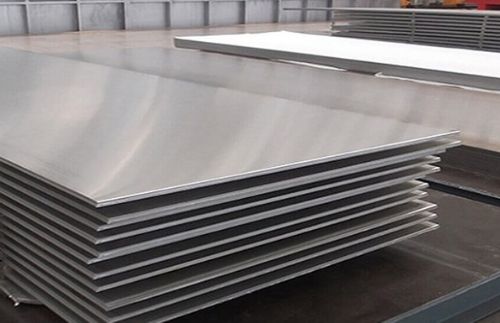

Incoloy Products India, Inconel Pipe, Inconel Tubes, Inconel Fittings, Inconel Sheet, Inconel Flanges Exporter in Mumbai, India.

Newzel Industries sells Incoloy alloys that are used in a wide range of industries and applications all over the world, such as

|

Aerospace Engineering |

Electrical Resistance Heating |

|

Oil and Gas Extraction |

Power Generation |

|

Automotive Engineering |

Electronics and Communications |

|

Petrochemical Processing |

Thermal Processing and Heat Treatment |

|

Chemical Processing |

Marine Engineering |

|

Pollution Control and Waste Processing |

Welding |

About Incoloy

A nickel-iron-chromium alloy called Incoloy has less than 50% nickel.

Incoloy is the perfect material for applications requiring a high temperature but less critical performance because of its higher ferrous content and accordingly cheaper cost. Another benefit is that it can be made very easily using the same tools and procedures as stainless steel.

There are many grades of this alloy as well, with the focus being mainly on resistance to aggressive kinds of corrosion, especially in watery conditions. While Incoloy in its basic form will be used extensively in everyday life, further alloying with strengthening materials adds resistance to physical degradation such as surface pitting and cracking as well as chemical and environmental corrosion.

It is a preferred option in the oil and gas industries due to its excellent resilience to situations with high chloride levels, seawater, brine, and sour gas. However, the most specialized Incoloy alloys are frequently employed in the most challenging chemical settings, including acids, wet cleaning, nuclear fuel, and the reactive atmospheres of furnaces, among others.

Characteristics of Incoloy

Excellent resistance to corrosion in aquatic situations

superior toughness resistance in high-temperature conditions

Excellent resistance to oxidation and carburization in high-temperature environments

strong creep-rupture resistance

Easily fabricated

Applications of Incoloy

Heat exchangers, Process piping, carburizing equipment, heating-element sheathing, nuclear steam-generator tubing

Chemical and petrochemical processing, power plants, industrial furnaces, heat-treating equipment

Pollution-control equipment, oil, and gas well piping, nuclear fuel reprocessing, acid production, pickling equipment

Equivalent Grades

ASTM Specifications

|

Alloy |

Pipe Smls |

Pipe Welded |

Tube Smls |

Tube Welded |

Sheet/Plate |

Bar |

Forging |

Fitting |

|

Alloy 800 (UNS N08800) |

B407 |

B154 |

B163 |

B515 |

B409 |

B408 |

B564 |

B366 |

|

Alloy 800H (UNS N08810) |

B407 |

B154 |

B163 |

B515 |

B409 |

B408 |

B564 |

B366 |

|

Alloy 800HT (UNS N08811) |

B407 |

B154 |

B163 |

B515 |

B409 |

B408 |

B564 |

B366 |

Compositions (Percentage) of Incoloy

|

Alloy name |

Fe |

Cr |

Al |

Ti |

C |

Y 2O 3 |

Cu |

Mn |

Co |

Ni |

P |

Si |

S |

Mo |

Nb |

|

020 |

35 |

19-21 |

0 |

0 |

0 |

0 |

3-4 |

<2 |

0 |

32-38 |

0 |

<1 |

0 |

2-3 |

0 |

|

028 |

29-40.4 |

26-28 |

0 |

0 |

0 |

0 |

? |

<2.5 |

0 |

30-34 |

0 |

0 |

0 |

3-4 |

0 |

|

803 |

29.435-42.64 |

25-29 |

0 |

0 |

0 |

0 |

0 |

<1.5 |

0 |

32-37 |

0 |

<1 |

0 |

0 |

0 |

|

945 |

balance |

19.5-23 |

0.01-0.7 |

0.5-2.5 |

0.005-0.04 |

0 |

1.5-3 |

1 |

0 |

45-55 |

0.03 |

0.5 |

0.03 |

3-4 |

2.5-4.5 |

|

945X |

balance |

19.5-23 |

0.01-0.7 |

0.5-2.5 |

0.005-0.04 |

0 |

1.5-3 |

1 |

0 |

45-55 |

0.03 |

0.5 |

0.03 |

3-4 |

2.5-4.5 |

|

330 |

Fe 43 |

17-20 |

0 |

0 |

0 |

0 |

0 |

<2 |

0 |

34-37 |

0 |

* |

0 |

0 |

0 |

|

825 |

Fe >22, ~33 |

19.5-23.5 |

<0.2 |

0.6-1.2 |

<0.05 |

0 |

1.5-3.0 |

<1.0 |

0 |

38-46 |

0 |

<0.5 |

<0.03 |

2.5-3.5 |

0 |

|

907 |

Fe 42 |

0 |

0.03 |

1.5 |

0 |

0 |

0 |

0 |

13 |

38 |

0 |

0.15 |

0 |

0 |

4.7 |