Steel is such a strong metal because it comes in a variety of grades and has its own chemical makeup. Knowing that all types of steel, including CNC machining steel, are made up of just two elements—iron and carbon—might come as a shock given the qualities of steel and how many distinct steel alloys there are.

However, when additional carbon and alloying components are added, the real difference becomes apparent. You see, the additional components (such as manganese and phosphorus) inserted during the formation of steel define its strength and endurance, which in turn decides its category for particular purposes. The chemical structure of the physical steel qualities, which are divided into four fundamental types, must be understood if you’re wondering what kind of steel to buy for your specific demands.

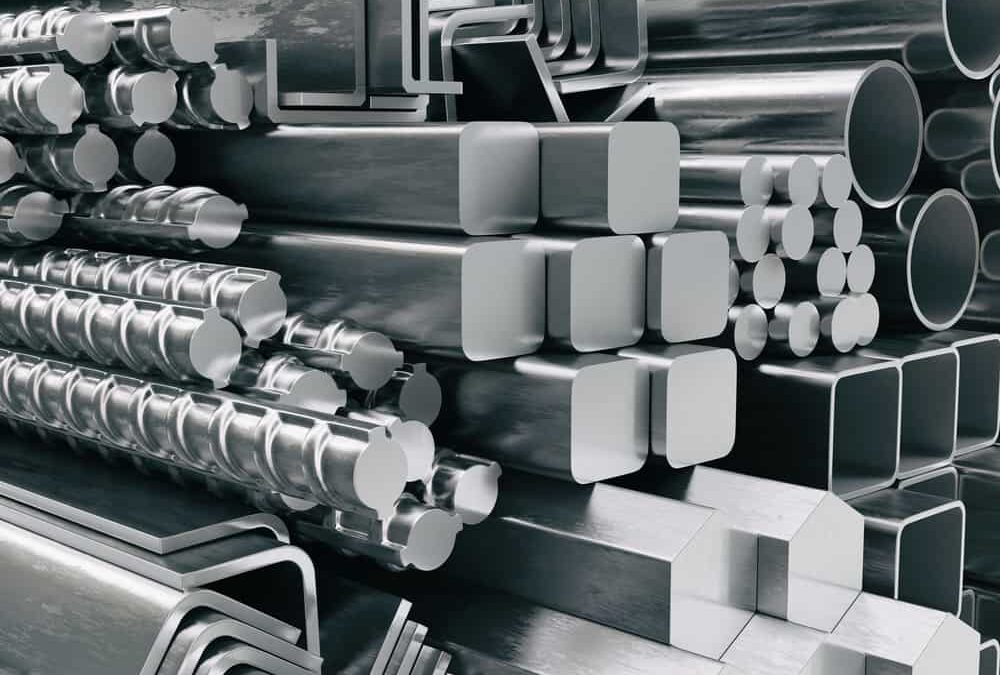

The Four Main Types of Steel

1 – Carbon Steel

Carbon steel is considered to be prone to corrosion and has a matte, dull appearance. There are three subtypes of this type in total: low, medium, and high carbon steel. Low carbon steel has a carbon content of about.30%, medium has.60%, and high has 1.5%. The fact that they only contain a very minimal amount of additional alloying elements is where the name truly derives from. Due to their extraordinary strength, they are frequently utilized to create objects like knives, high-tension wires, automotive components, and other related products.

90% of all steel produced is made of carbon steel.

The medium carbon steel C45/AISI 1045 is ideal for parts like gears, bolts, all-purpose axles and shafts, keys, and studs. Get a quote right away for your carbon steel item.

2 – Alloy Steel

The next type of steel is alloy steel, which is a combination of multiple metals including nickel, copper, and aluminum. These are preferred for some automobile parts, pipelines, ship hulls, and mechanical projects since they are more corrosion-resistant and tend to be on the cheaper side. This one’s potency is based on how concentrated its constituent ingredients are.

High core strength and toughness, heavy-duty bearings, cam followers, clutch dogs, compressor colts, fan shafts, heavy-duty gears, and pump shafts are all made of the alloy steel AISI 4317/18NiCrMo5. Instantaneous quote for your alloy steel part

3 – Tool Steel

Tool steel is renowned for being tough and resistant to heat and scuffs. The term comes from the fact that they are frequently employed in the production of metal tools like hammers. Tool steel offers such high levels of durability and heat resistance because they are mostly composed of elements like cobalt, molybdenum, and tungsten.

4 – Stainless Steel

Stainless steels are maybe the most well-known variety on the market, but they are certainly not the least. This kind is glossy and often contains 10 to 20 percent chromium, which serves as its primary alloying component. This combination enables the steel to be both corrosion-resistant and easily moldable into a variety of shapes. Stainless steel is used in surgical instruments, home appliances, silverware, and even as the outside cladding for commercial and industrial structures due to its versatility, quality, and ease of manipulation.

The fact is that stainless steel comes in over 100 different grades, making it a very adaptable and adjustable material.

Stainless steel 316L is appropriate for heat exchangers, pipelines, external building materials in coastal areas, watch bracelets, cases, and other components for high-tech timepieces, marine equipment, chemicals, dyes, and the food industry. Get a quick quote on your stainless steel part

Steel Grades to Take Note of

Engineers, scientists, architects, and even government organizations frequently employ steel grading to bolster their faith in the reliability and caliber of the materials.

The ASTM Grading System – This one prefixes each metal with a letter according to its classification. For instance, the letter “A” stands for metals like steel and iron. The exact characteristics of that metal are then reflected in a sequential number that is given to it.

The SAE Grading System – A four-digit number is used for classification in this grading system. The last two describe the carbon content of that particular metal, whereas the first two reflect the type of steel and the concentration of alloying elements.

Conclusion

There were barely 500 million tonnes of steel produced globally in 1967. However, that figure increased to over 1,600 million in 2016. Additionally, steel accounts for 55% of the weight of a conventional car, according to The World Steel Association. Given this situation, it is difficult to envision a world without steel. The applications for steel are essentially limitless because there are more than 3,500 different grades of steel. Each form of steel, from fabrication to CNC machining, has a specific use and set of properties that may satisfy almost every requirement.

Last but not least, the four varieties of steel that are currently used result from the use of various steel alloys. Therefore, if you are considering buying steel, take the time to identify the ideal steel qualities you require and the appropriate grade to manage the task you are trying to complete. By doing this now rather than discovering after the fact that you made the wrong choice, you will thank yourself.

Read More :

All About Mild Steel: MS Channels or commonly known as C- channels or ISMC, because their C-like shape is represented by the Web height & Flange width of the channel.

Pros and Cons of Carbon Steel: What You Should Know: One of Carbon steel’s strengths is also one of its weaknesses. Carbon steel is very strong, but it’s hard to work with and hard to shape into different shapes because of how strong it is. Another bad thing about carbon steel is that it is easy to rust.