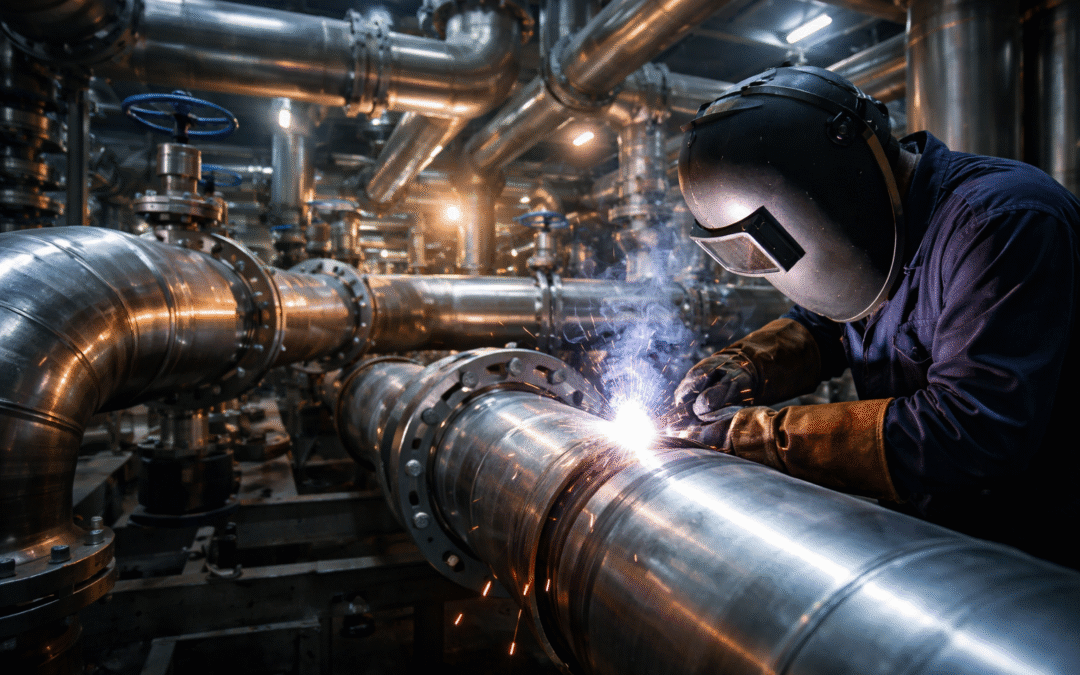

Welding in piping is more than just joining metal; it’s about guaranteeing strength, dependability, and safety in every connection. Even the best-designed piping systems will fail under high pressure and temperature if the welds are not properly completed.

Here’s why welding is important in plumbing.

Strength and Integrity – Holds pipes and fittings together even in harsh conditions.

Leak-Proof Operation: Prevents leaks in essential oil, gas, and chemical systems.

Durability – Durability ensures that pipelines last longer and have fewer breaks.

Safety – Safety and compliance are guided by ASME, AWS, and ISO standards.

Common types of welds in piping:

Butt Weld (BW) – End-to-end pipe joining (most prevalent in process piping).

Socket Weld (SW): A pipe is placed into a fitting and welded around the edge.

Fillet Weld – A triangular weld used for T-joints and structural supports.

For high-strength joints, a full penetration weld ensures complete fusion through thickness.

Tack Welds are temporary welds that hold alignment before final welding.

As a Piping Detailer, We are responsible for weld mapping, which involves recognizing the correct weld type and symbol on isometric drawings. This guarantees that fabrication teams work with precision, safety, and compliance.

Welding is more than just a fabrication phase; it serves as the foundation for all safe and reliable piping systems.