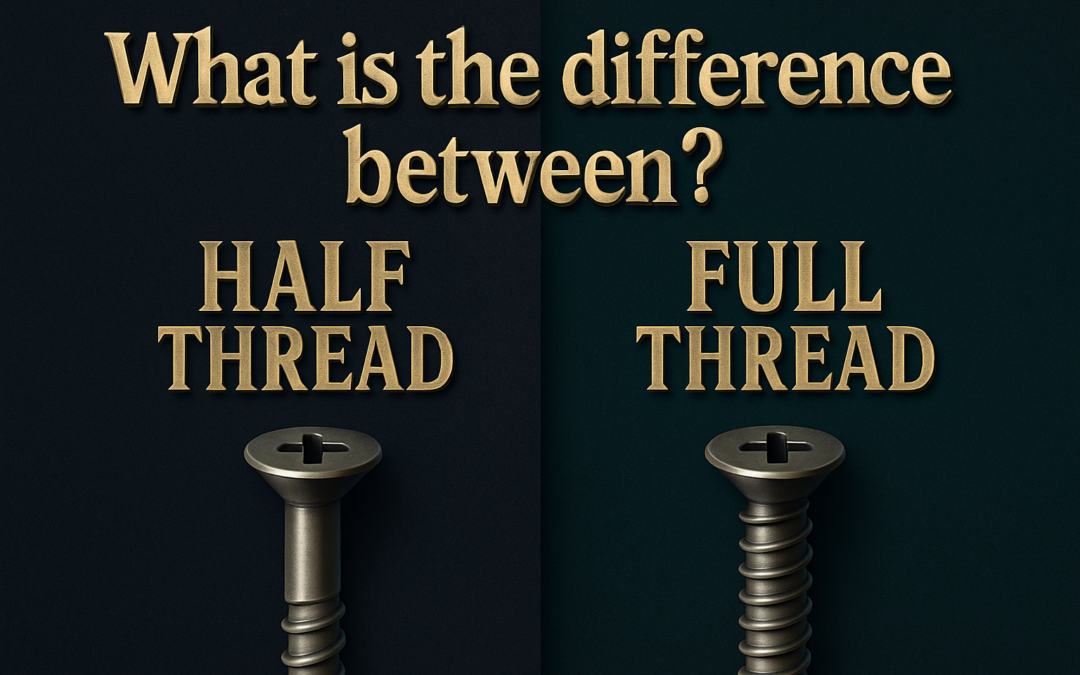

Threads are an important component of fasteners and piping components because they determine their strength and suitability for various applications and usage situations. To ensure optimal project performance, selecting threaded components necessitates understanding the differences between half-thread and full-thread. This blog will look at their differences, applications, and benefits, as well as key phrases like threaded full coupling, Carbon Steel Threaded Full Coupling, and Mild Steel Forged Threaded Full Coupling, to provide a thorough knowledge.

Understanding Threads in Fasteners and Couplings

Threads are helical structures used to screw components into position. They offer grip, strength, and stability. Whether in bolts, screws, or couplings, the kind of threading influences the component’s function.

What is a Full Thread?

A full-thread component has threads running throughout its entire length. The threads in fasteners such as bolts begin at the head and continue until they reach the tip. Threaded complete couplings include threads from end to end, ensuring a secure and tight fit.

Advantages of Full Thread Components:

Maximum Grip Strength – The threaded design of the component ensures maximum holding power.

Better Load Distribution – Ideal for applications that require uniform force distribution.

High Tensile Strength – Ensures strong connections in structures and pipe systems.

Common Uses for Full Thread Components:

Used in fastening applications that require greater grip.

Carbon Steel Threaded Full Coupling provides robust pipeline connections.

Used in Mild Steel Forged Threaded Full Couplings for industrial and construction purposes.

What is a Half Thread?

A half-threaded component has threads that cover only a piece of its length, leaving the remainder smooth. In bolts, this smooth part is known as the shank, and it provides higher shear resistance in certain applications.

Advantages of half threaded components:

Better Shear Resistance – The smooth portion increases strength against sideways forces.

Reduced Stress Concentration – Helps to avoid breaking and failure under severe loads.

Ideal for Alignment Applications – Common in machines where accurate positioning is required.

Common Uses of Half-Thread Components:

Used for construction and structural frameworks.

Common in machinery that requires movement.

Found in mechanical couplings that require stability without excessive thread engagement.

Key Differences between Half Thread and Full Thread

| Feature | Full Thread | Half Thread |

| Thread Coverage | Fully threaded from end to end | Partially threaded, smooth section remains |

| Grip Strength | High, due to full engagement | Moderate, but offers better shear strength |

| Tensile Strength | Higher, due to full-length threading | Slightly lower but has better shear resistance |

| Best for | High-strength fastening and secure pipeline connections | Structural applications with shear loads |

Which One Should You Choose?

Your application will determine whether you should use half-thread or full-thread components.

If you require maximum grip and tensile strength, choose full-thread components such as a Carbon Steel Threaded Full Coupling.

If your application requires strong shear resistance, a half-threaded component would be a better option.

Mild Steel Forged Threaded Full Couplings are widely utilized in industrial applications requiring durability and strength.

Conclusion

The selection of components necessitates a fundamental grasp of the distinction between full-thread and half-thread topologies. complete-thread components have great grip strength, making them ideal for threaded complete couplings and structural applications. Half-threaded components have higher shear resistance qualities, making them suitable for specific applications. To determine whether to use carbon steel threaded full couplings or mild steel forged threaded full couplings, consider the application’s durability, strength, and performance requirements.

Your grasp of the problem enables you to choose components that improve the performance, operational life, and safety of your fastening or pipe system.