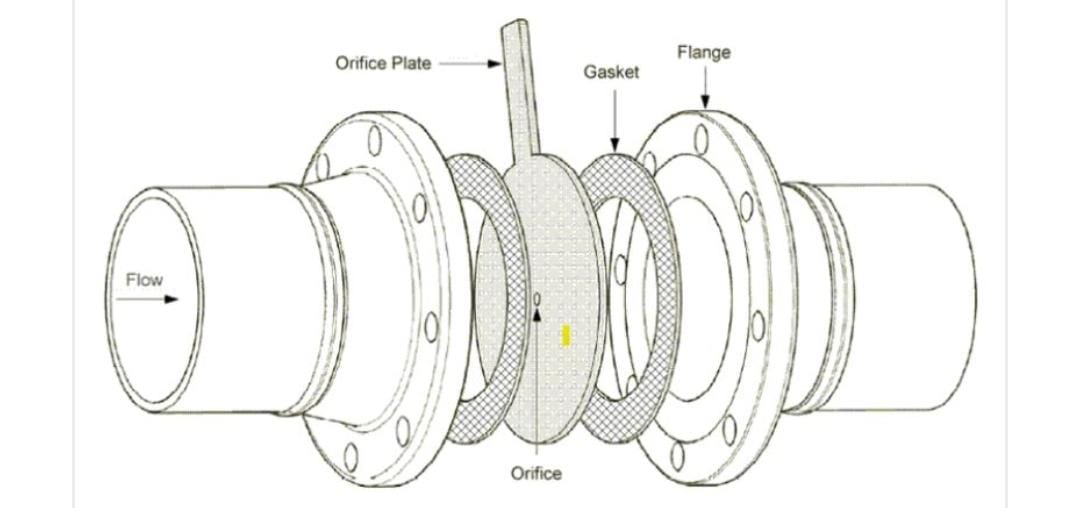

An orifice plate is a thin plate with a circular hole, inserted into a pipe to measure the flow rate of a fluid. By creating a controlled restriction in the pipe, it accelerates the fluid and reduces pressure. The resulting pressure difference between the upstream and downstream sides of the plate is measured, allowing calculation of the flow rate. Orifice plates are commonly used for flow measurement, pressure reduction, or flow restriction, and are often referred to as restriction plates.

Key characteristics of orifice plates include:

• Concentric or eccentric: Concentric plates have the hole centered in the pipe, while eccentric plates have the hole off-center.

• Sharp-edged or rounded: Sharp-edged plates have a sharp edge around the hole, while rounded plates have a rounded edge.

• Beta ratio: The ratio of the hole diameter to the pipe diameter.

Orifice plates are commonly used in various industries, including:

• Oil and gas

• Chemical processing

• Water and wastewater treatment

• Food and beverage

Advantages of orifice plates:

• Low cost

• Simple design and installation

• Wide range of flow rates

• Accuracy

Disadvantages of orifice plates:

• Permanent pressure loss

• Sensitivity to flow conditions

• Not suitable for dirty fluids

Overall, orifice plates are a reliable and cost-effective method for measuring fluid flow rates in many applications.