The efficient management of steam and high-temperature fluids is critical in many industrial processes. The condensate pot is an important component in this management process. This device, also known as a condensate seal pot or steam condensate pot, is necessary for protecting pressure transmitters and other equipment from the effects of steam. In this essay, we will look in depth at the working concept of condensate pots, as well as their design, applications, and importance in industrial operations.

What is a Condensate Pot?

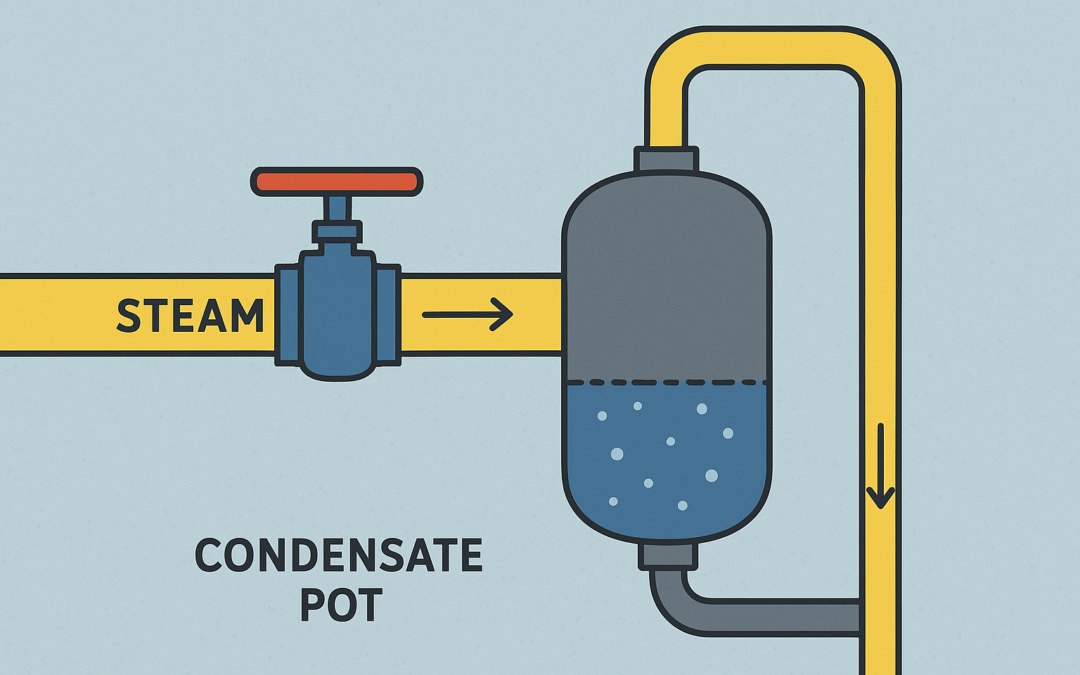

A condensate pot is a device for collecting and managing condensate, the liquid that forms when steam or vapor cools and condenses. This gadget is critical in many industrial operations that involve steam. By isolating delicate equipment from high temperatures and steam, the condensate pot assures correct readings and safeguards precious instrumentation.

How Does a Condensate Pot Work?

Understanding the condensate pot working principle entails examining how it operates in an industrial setting. Here’s the step-by-step breakdown:

Steam Flow and Condensation: When steam travels down a pipeline and into the condensate pot, it encounters a cooler environment. As steam cools, it condenses to form water. This liquid settles at the bottom of the saucepan.

Formation of a Seal: The condensate gathered at the bottom of the pot forms a seal. This seal keeps steam from contacting the pressure transmitter or other sensitive electronics directly. The seal guarantees that only the pressure of the process fluid (not steam) is monitored, which is critical for obtaining correct results.

Draining Condensate:To keep the system running well, the accumulated condensate must be emptied on a regular basis. This is typically accomplished by the use of a drain valve, which allows the liquid to be withdrawn without affecting the system’s operation. Proper draining ensures that the condensate pot remains functional and can offer accurate data.

Key components of a condensate pot.

A typical condensate pot consists of several key components:

Body: The main container that stores the condensate. It is often constructed of strong materials that can withstand high temperatures and pressures.

Inlet and Outlet: Steam pipes allow steam to enter and exit the pot. The efficiency with which condensate is collected can be influenced by the pipe design.

Drain Valve: A valve used to drain accumulated condensate. To keep the pot working properly, empty it on a regular basis.

Pressure Connection: This is where the pressure transmitter is attached to the pot, ensuring that only the pressure of the process fluid is detected.

Different Designs of Condensate Pots

Condensate pots come in a variety of styles to suit different needs. Here are some instances.

Condensate Pot: Newzel Industries is a well-known brand in the industry, offering condensate pots that are reliable and precise. Their design ensures durability and effectiveness in various industrial applications.

Applications of Condensate Pots

Condensate pots are utilized in a variety of industries, including:

Oil and Gas: Condensate pots are used in the oil and gas industry to manage steam and protect pressure transducers. This ensures precise pressure readings and prevents equipment damage.

Chemical Processing: Condensate pots are used in chemical plants to handle high-temperature fluids while protecting delicate equipment. This helps to ensure process precision and equipment longevity.

Power Generation: Condensate pots in power plants are critical for steam management and the effective operation of pressure transmitters and other equipment.

Advantages of Using a Condensate Pot

There are various advantages of employing a condensate pot in industrial systems:

Protects Equipment: A condensate pot protects sensitive instruments from high-temperature steam, extending the life of pressure transmitters and other equipment.

Ensures Accuracy: The condensate pot prevents steam from impacting the pressure transmitter, therefore ensuring accurate pressure measurements.

Improves System Efficiency: Properly constructed and maintained condensate pots improve industrial system efficiency by providing precise pressure measurements and protecting equipment.

Condensate Pot Design Considerations

When choosing or creating a condensate pot, numerous variables must be considered:

Material: The pot should be made of materials that can withstand extreme heat and pressures. Common materials include stainless steel and various alloys.

Size and Capacity: The condensate pot’s size should match the system’s requirements. It should be large enough to capture the estimated volume of condensate while being efficient.

Drainage System: The design should include a reliable drainage system for removing condensate without interrupting the system.

Condensate Pot Manufacturers and Suppliers

The design should include a reliable drainage system for removing condensate without interrupting the system.

Condensate Pot Manufacturers in India: India has multiple manufacturers who offer a variety of condensate pots for various industrial purposes. These manufacturers provide a variety of designs and adaptations to satisfy individual requirements.

Condensate Pot Supplier in India: Suppliers in India provide condensate pots from a variety of manufacturers, ensuring that organizations have access to high-quality components.

Condensate Pot Exporter in India: Indian exporters play an important role in providing condensate pots to overseas markets. We assure that high-quality components reach international clients.