A heat exchanger is a device that transfers heat from two or more fluids (liquids or gasses) without mixing them. It is essential in many sectors because it regulates temperatures, improves energy efficiency, and aids processes that require precise thermal control.

How Does a Heat Exchanger Work?

Heat exchangers transfer heat between fluids using two main processes:

Conduction

Heat transfers from the hotter fluid to the cooler one via a solid barrier, such as the heat exchanger’s walls.

Convection:

Fluid movement improves heat transfer, and pumps or fans that increase fluid flow help to promote efficiency, These concepts are crucial to the successful operation of heat exchangers in a variety of applications, resulting in optimal thermal management, The movement of fluids via a heat exchanger has a considerable influence on its performance.

Counterflow:

Fluids travel in opposite directions, increasing the temperature gradient and ensuring maximum efficiency.

Parallel Flow:

Fluids move in the same direction, resulting in a lower temperature gradient and decreased efficiency compared to counterflow.

Crossflow:

Fluids flow perpendicular to each other and are commonly employed in compact systems such as air conditioning units.

Choosing the appropriate flow configuration is critical for optimizing heat transfer and boosting system performance.

Types of Heat Exchangers

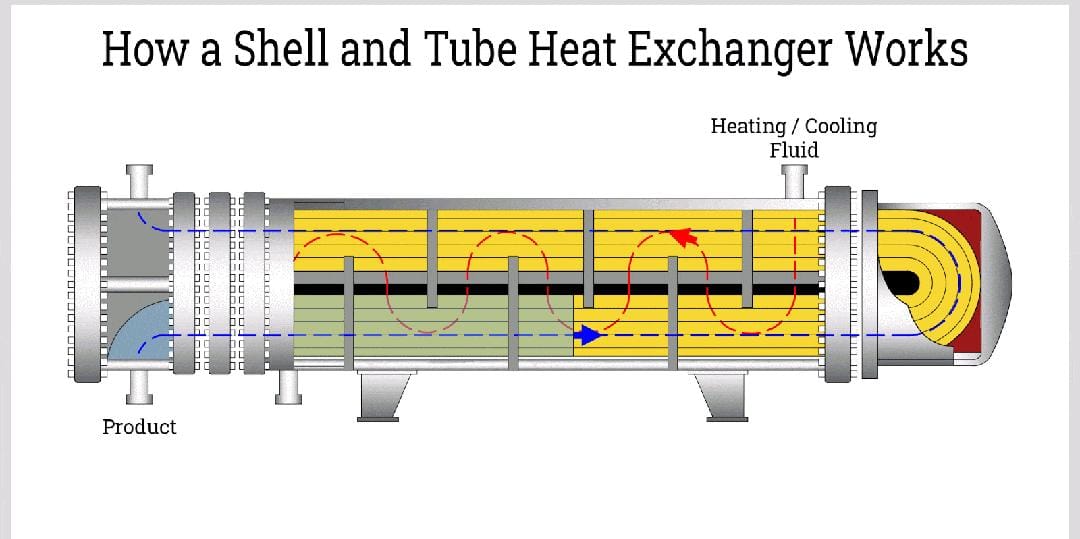

Shell and Tube:

Handles high pressures in oil refineries, chemical facilities, and power plants.

Plate:

Compact design with effective heat transfer, suitable for HVAC and food processing.

Double Pipe:

In small-scale enterprises, heat transmission is simple and effective at low to moderate levels.

Air Cooled:

Cooling is accomplished through the use of ambient air, making it ideal for power generation and refrigeration.

Spiral:

Efficient for viscous fluids; utilized in the food and pharmaceutical industries.

Finned Tube:

Fins enhance heat transfer and are extensively utilized in HVAC, automotive, and industrial applications.

These diversified designs offer optimal performance in a variety of heat control applications.

Heat exchangers are essential components in many industries, driving efficiency and accurate temperature control.

HVAC Systems.

It is essential for heating and cooling in home, commercial, and industrial applications.

Chemical Processing

Used to keep temperatures under control in reactors and distillation columns.

Power Generation

Improve the efficiency of steam turbines, condensers, and cooling systems by minimizing waste heat.

Food and Beverage

Pasteurization, chilling, and heating are all necessary procedures throughout manufacture.

Automotive Industry

Car radiators and air conditioning systems play an important role in regulating engine and cabin temperatures.

These examples highlight the relevance of heat exchangers in improving performance and energy efficiency across a wide range of industries.

Newzel Industries delivers heat exchanger components—such as tubesheets, baffle plates, body, and shell flanges—in fully finished conditions, ready for immediate installation. This approach simplifies the process for our customers, making installation more efficient and hassle-free.