Read this to Know Everything About It!

UNS S31803 and S32205 denote alloys with more similarities than differences. Firstly, they are both stainless steel with identical elemental components. Both S31803 and S32205 belong to the duplex 2205 family, which implies they comprise roughly equal proportions of austenite and ferrite. Secondly, they are both exceptionally strong and durable alloys. S31803 and S32205 are both incorporated into some of the more hard-wearing and inhospitable production processes that need materials that can resist repeated and continuous rides through the proverbial ringer.

Everything you need to know about UNS S32205 and S31803 and their applications

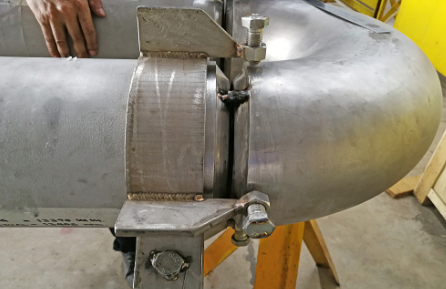

UNS S32205 is a two-phase, ferritic, austenitic stainless steel alloyed with 22% chromium, 3% molybdenum, and 5 to 6% nickel. It is the most widely used grade of duplex stainless steel and is characterized by high yield strength, which doubles that of the standard austenitic stainless steel grades. It has high resistance to pitting and crevice corrosion and is excellent in most caustic environments. It also has good weldability.

Its Applications:

- pulp mills

- food processing

- oil and gas piping

- chemical processing, and more.

UNS S31803 is a duplex grade with a ferritic-austenitic microstructure. This alloy consists of around 40–50% ferrite in the annealed condition. The duplex microstructure has the high strength of the ferritic grades while maintaining the corrosion resistance of the austenitic grades.

Its Application:

- Fuel gas filters

- Chemical tanks

- Heat exchangers

- Acetic acid distillation elements

Let’s Know About the Differences

The initial specification of the duplex stainless steel was set as UNS S31803. But other manufacturers constantly produced this grade and upgraded it to the highest allowed specification. This increased the corrosion performance. This also allowed the nitrogen additions to activate rather than be just a background element. The highest performing duplex grade increased the levels of chromium, molybdenum, and nitrogen. UNS S32205 was introduced in order to differentiate the duplex stainless steel produced at the end of the composition range. The main distinctions are:

UNS S32205 contains higher nitrogen content which gives it extra strength. Hence, it is super safe. It provides an additional protective cover against any corrosive compounds. UNS S32205’s heightened corrosion resistance gives it a significant distinction from UNS S31803. UNS S32205 was a highly dependable piece of duplex steel, but now it has an enriched propensity to protect against wear and tear and preserve the quality of any application.

Why is Duplex 2205 a Superior Steel Solution?

Duplex stainless steels account for over 80% of the consumption of duplex, super duplex, and hyper duplex grades. It has an unrivaled capacity for anti-corrosion and an unparalleled heat and energy absorption capacity. Its resistance to some of the most reactive chemicals and compounds means that S32205 is used in applications where other materials with fewer components would not bear the pressure. Suplex S32205 is certainly counted for tasks like chemical treatment, material handling and processing projects, and paper production. The family of duplex grades has twice the strength and provides a significant uplift in corrosion resistance. Their pitting corrosion resistance will increase if the chromium content is increased. The Pitting Resistance Equivalent Number (PREN) which refers to an alloy’s pitting resistance also includes a number of other elements in its formula. This is how the difference between S31803 and S32205 developed.

Newzel Industries deals in all kinds of stainless steel and alloy steel products, incorporating all kinds of steel solutions. Contact us to know more about our solutions. We deliver advanced steel solutions that provide the strength, versatility, and lasting durability needed to build a stronger future for your company.

Get a free quote today!