by user | Sep 18, 2025 | Blog

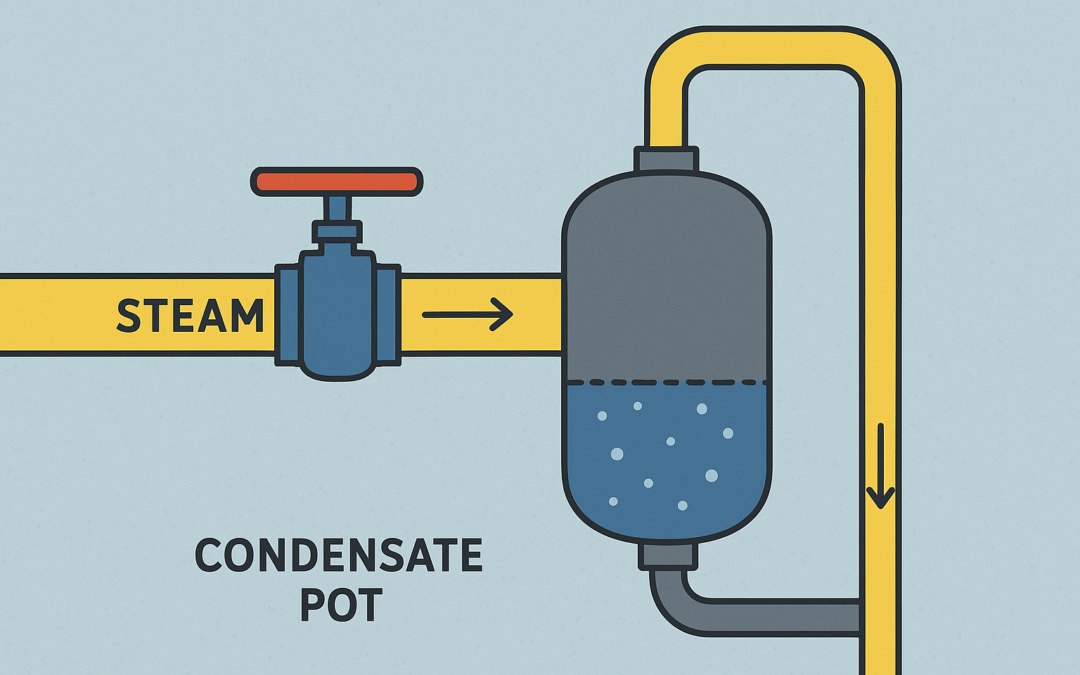

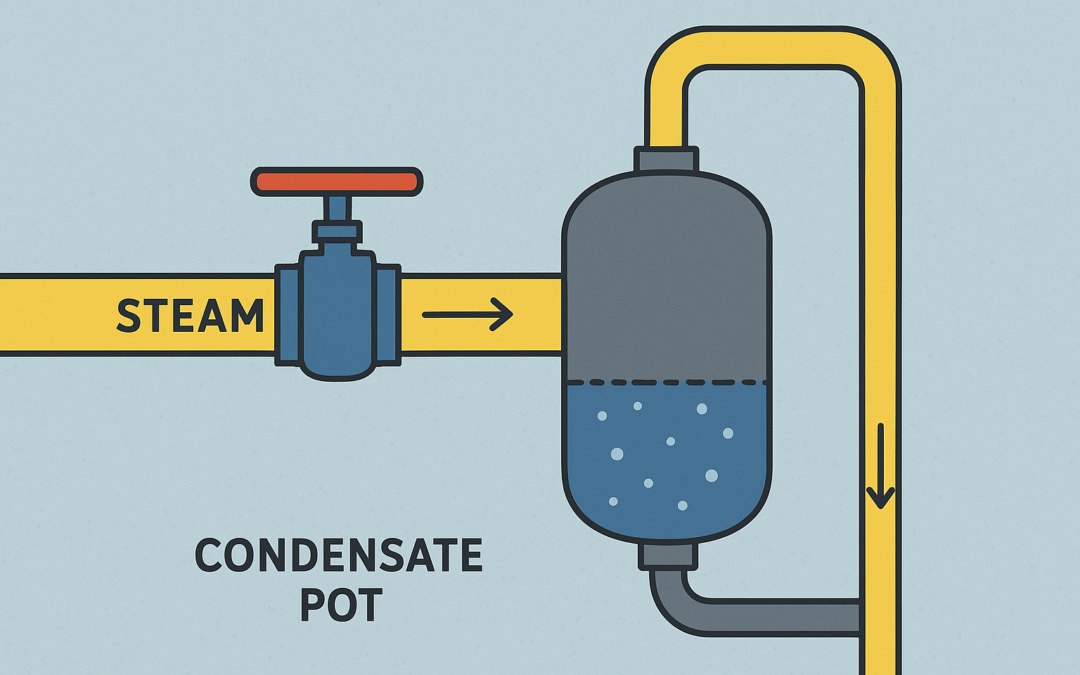

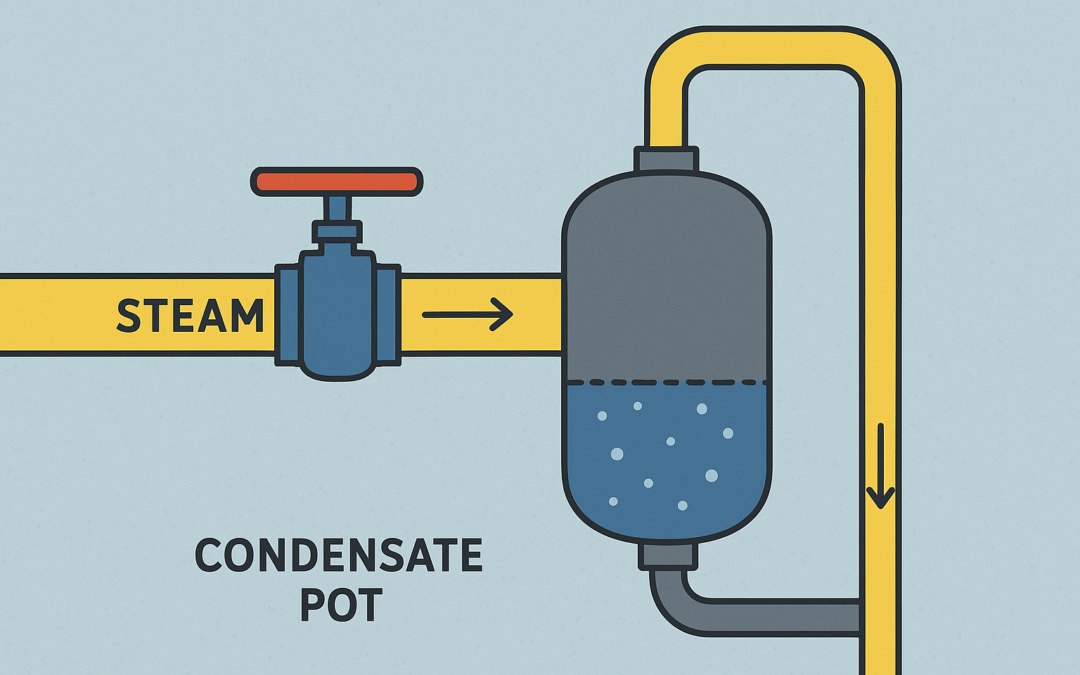

The efficient management of steam and high-temperature fluids is critical in many industrial processes. The condensate pot is an important component in this management process. This device, also known as a condensate seal pot or steam condensate pot, is necessary for...

by user | Sep 13, 2025 | Blog

SS 304 (18-8 Stainless Steel)SS 316 (18-10 Stainless Steel)Corrosion ResistanceGoodExcellentPitting ResistanceModerateHighCrevice Corrosion ResistanceModerateHighStress Corrosion Cracking ResistanceModerateHighHeat ResistanceUp to 870°CUp to 870°CCostLess...

by user | Sep 6, 2025 | Blog

ASTM A36 is a commonly used mild and hot rolled steel with excellent welding and manufacturing properties. It is adaptable and can perform drilling, grinding, punching, tapping, and machining, among other tasks. These features give dependability and ease of use,...

by user | Aug 16, 2025 | Blog

Stainless steel and galvanized steel are two of the most used materials for industrial and building applications. While they may appear to be similar, they differ in composition, manufacturing procedures, corrosion resistance, and long-term performance. Choosing the...

by user | Aug 10, 2025 | Blog

Gauge Measurement Overview Gauge is a commonly used system for measuring the thickness of metal sheets, which is necessary in manufacturing, fabrication, and building. The gauge number indicates the thickness of the sheet and impacts its strength. For example,...

by user | Aug 7, 2025 | Blog

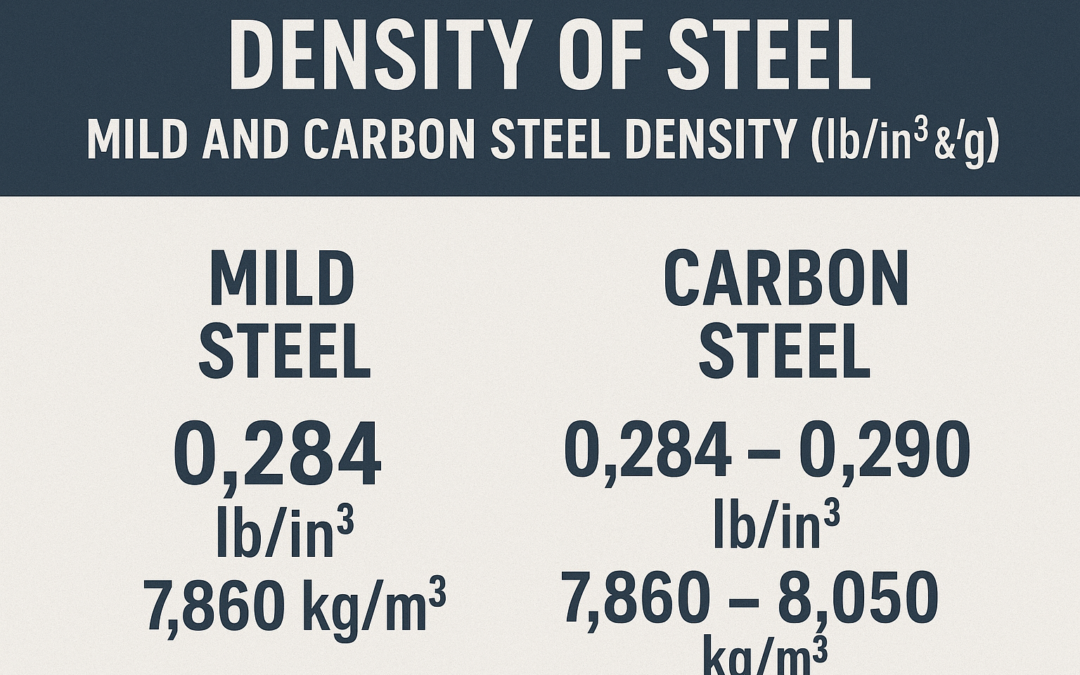

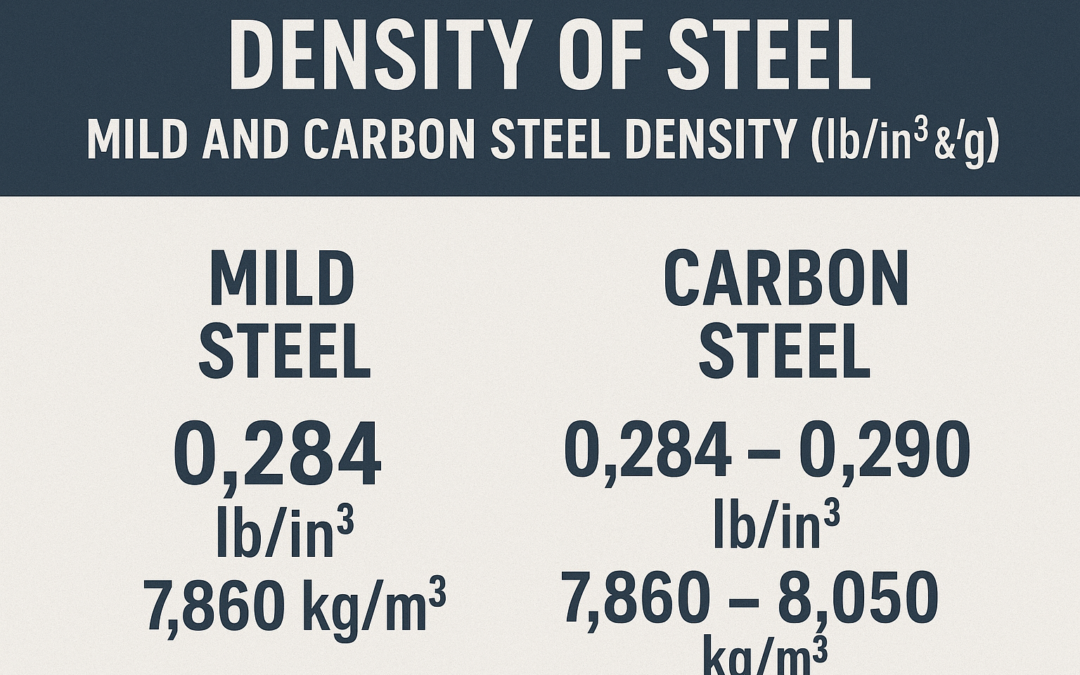

What is the Density of Steel? Steel has a density of 7.85 g/cm³ or 7850 kg/m³, equivalent to 490 pounds per cubic foot. Steel’s high density makes it a strong and dependable material suitable for demanding building tasks. Suppliers such as Buy A Beam provide...