by user | Feb 8, 2026 | Blog

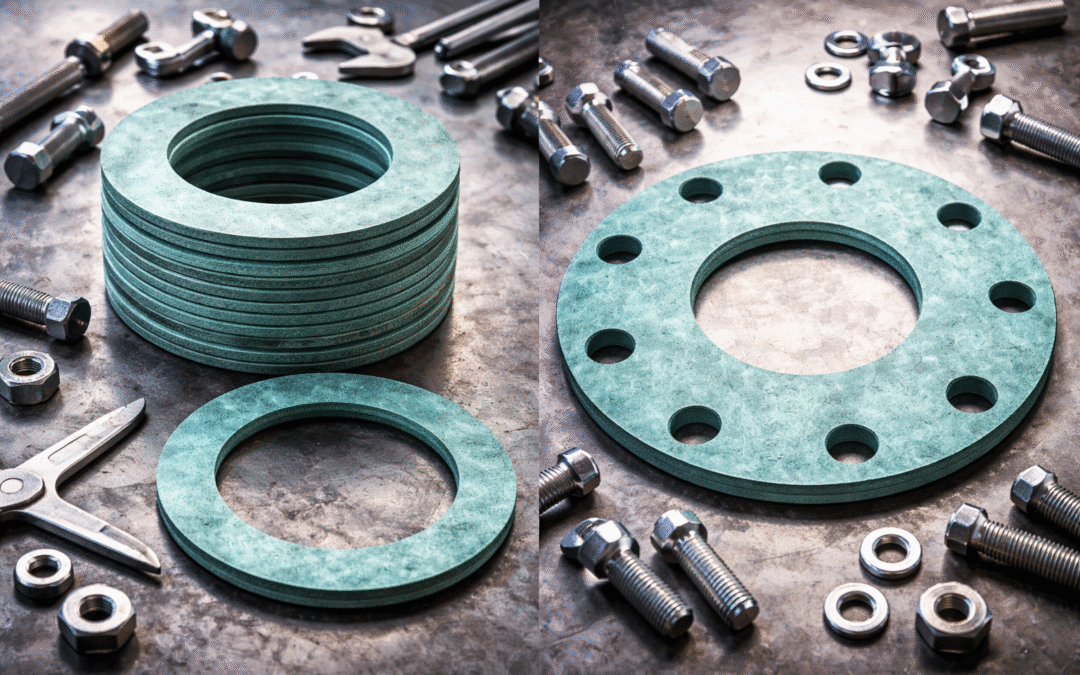

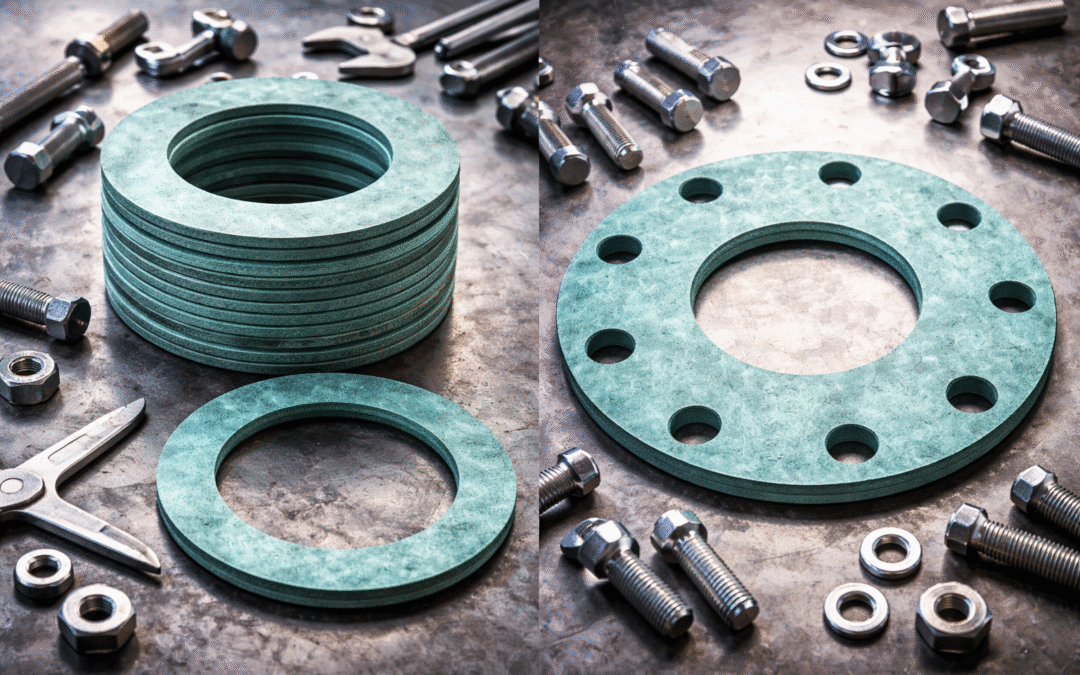

When sealing raised or flat face flanges, there are two gasket shapes available: ring-type and full-face. Each has advantages, so you should choose which is ideal for your application before ordering and installing. First, let’s look at the many sorts of flanges...

by user | Feb 8, 2026 | Blog

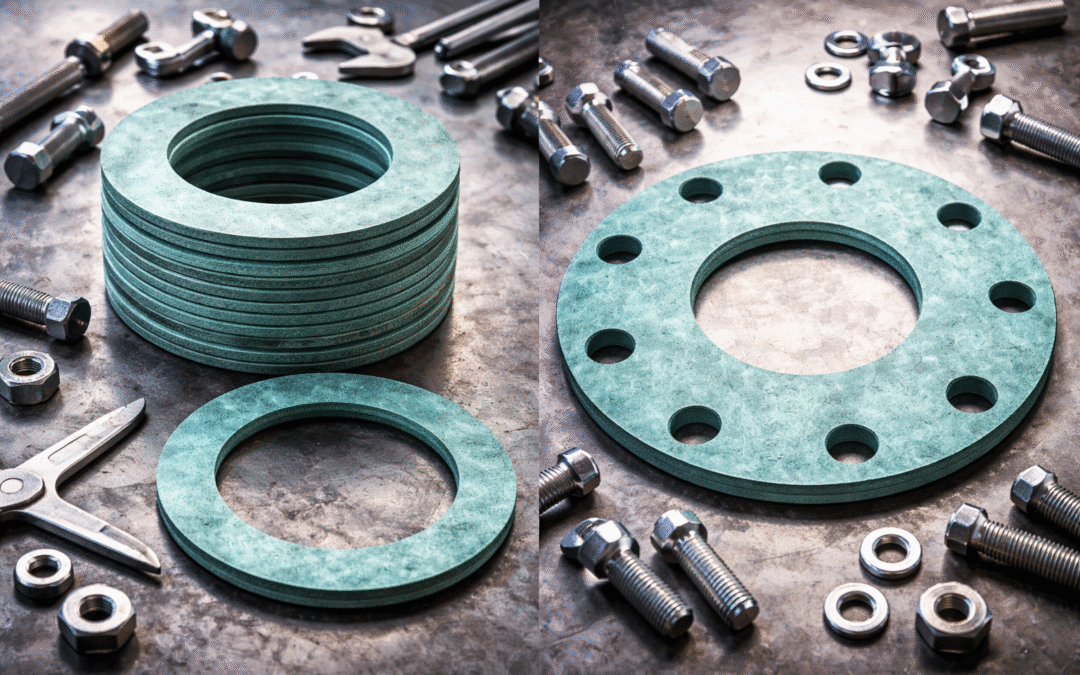

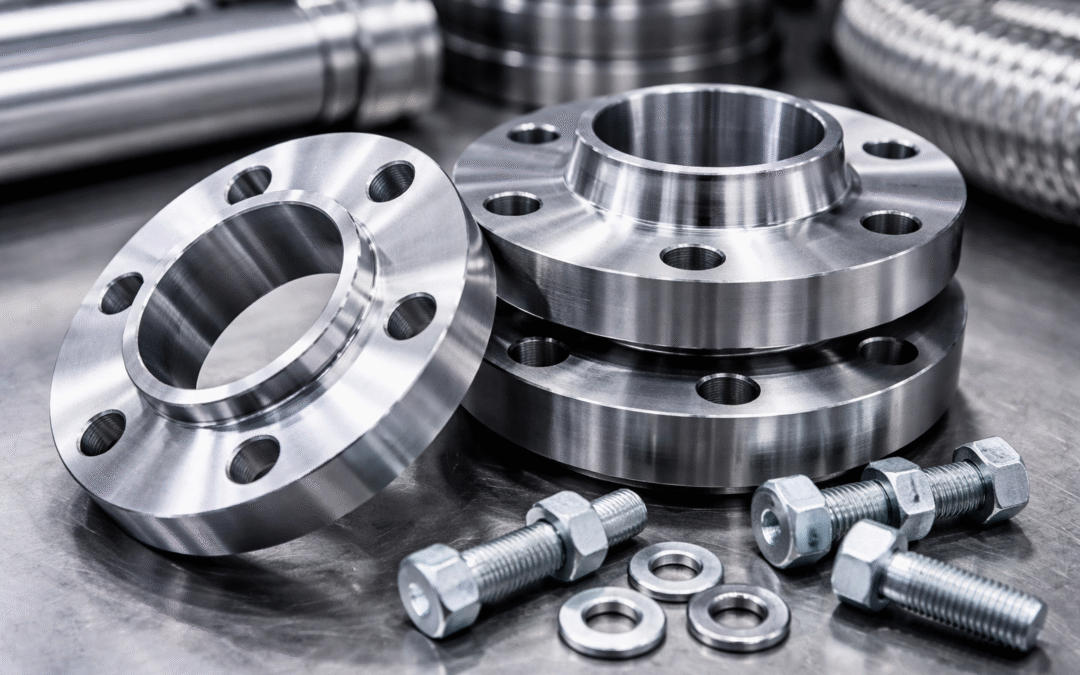

Slip-on flanges, also known as ‘hubbed flanges’, include a low-profile hub. This sort of flange is often attached to a pipe with one or two fillet welds (one outside and one inside the flange), however it is possible to utilize only one weld. Slip-on...

by user | Jan 10, 2026 | Blog

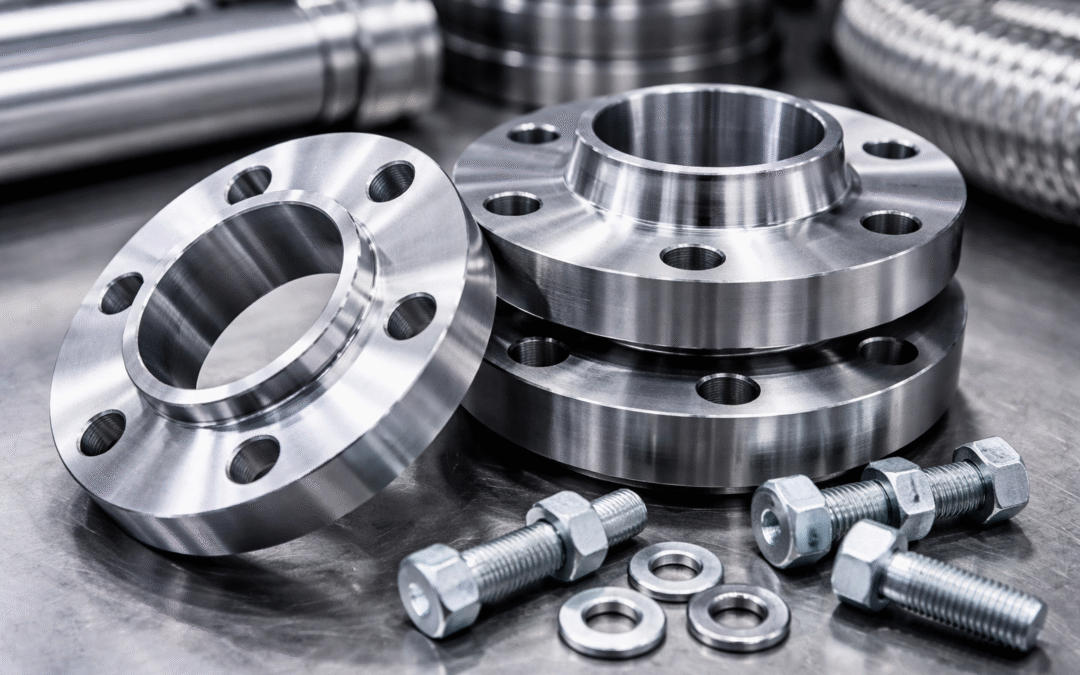

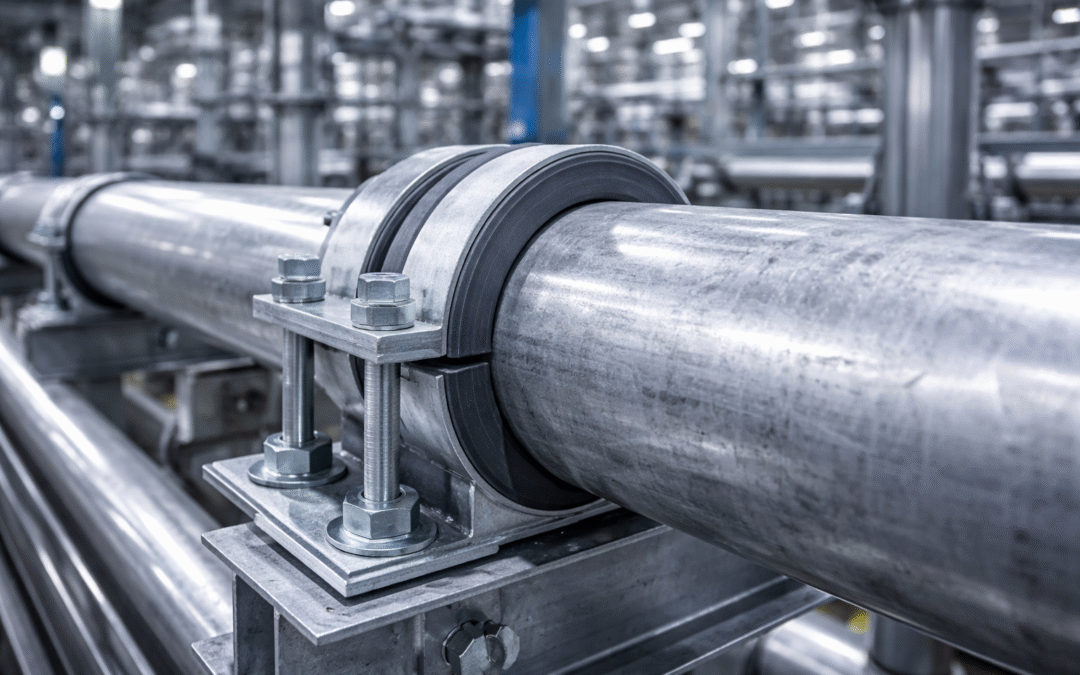

In reality, leak prevention is frequently centered on gaskets, flanged joints, and pipe material selection. This attention is necessary, but not sufficient. From an asset integrity standpoint, the interface between pipe and pipe support is a systemic influencing...

by user | Jan 1, 2026 | Blog

HDPE (High-Density Polyethylene) pipes are thermoplastic pipes known for: High chemical resistance Flexibility and durability Corrosion-free performance Commonly used for water, gas, slurry, and chemical transport in oil & gas facilities Key Characteristics...

by user | Dec 22, 2025 | Blog

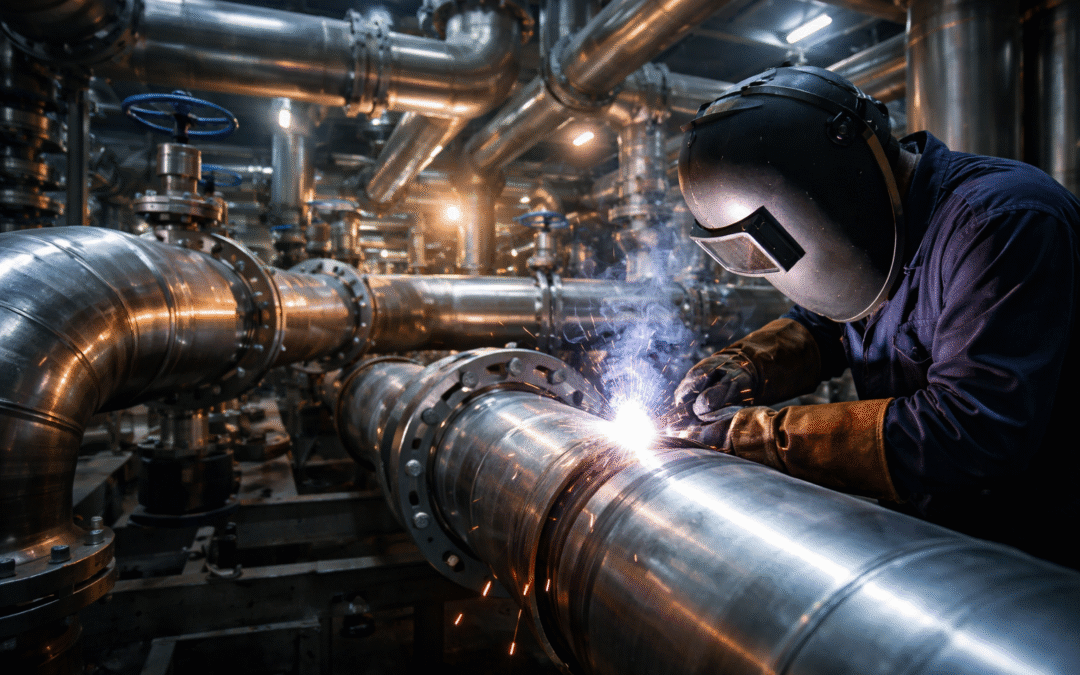

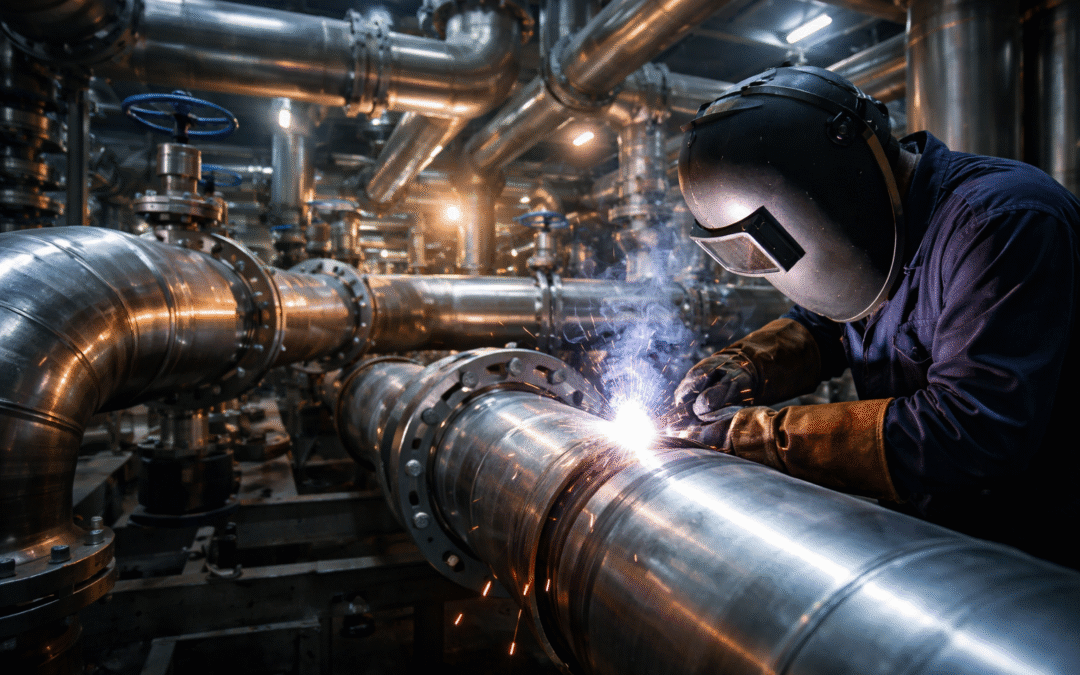

Welding in piping is more than just joining metal; it’s about guaranteeing strength, dependability, and safety in every connection. Even the best-designed piping systems will fail under high pressure and temperature if the welds are not properly completed....

by user | Dec 13, 2025 | Blog

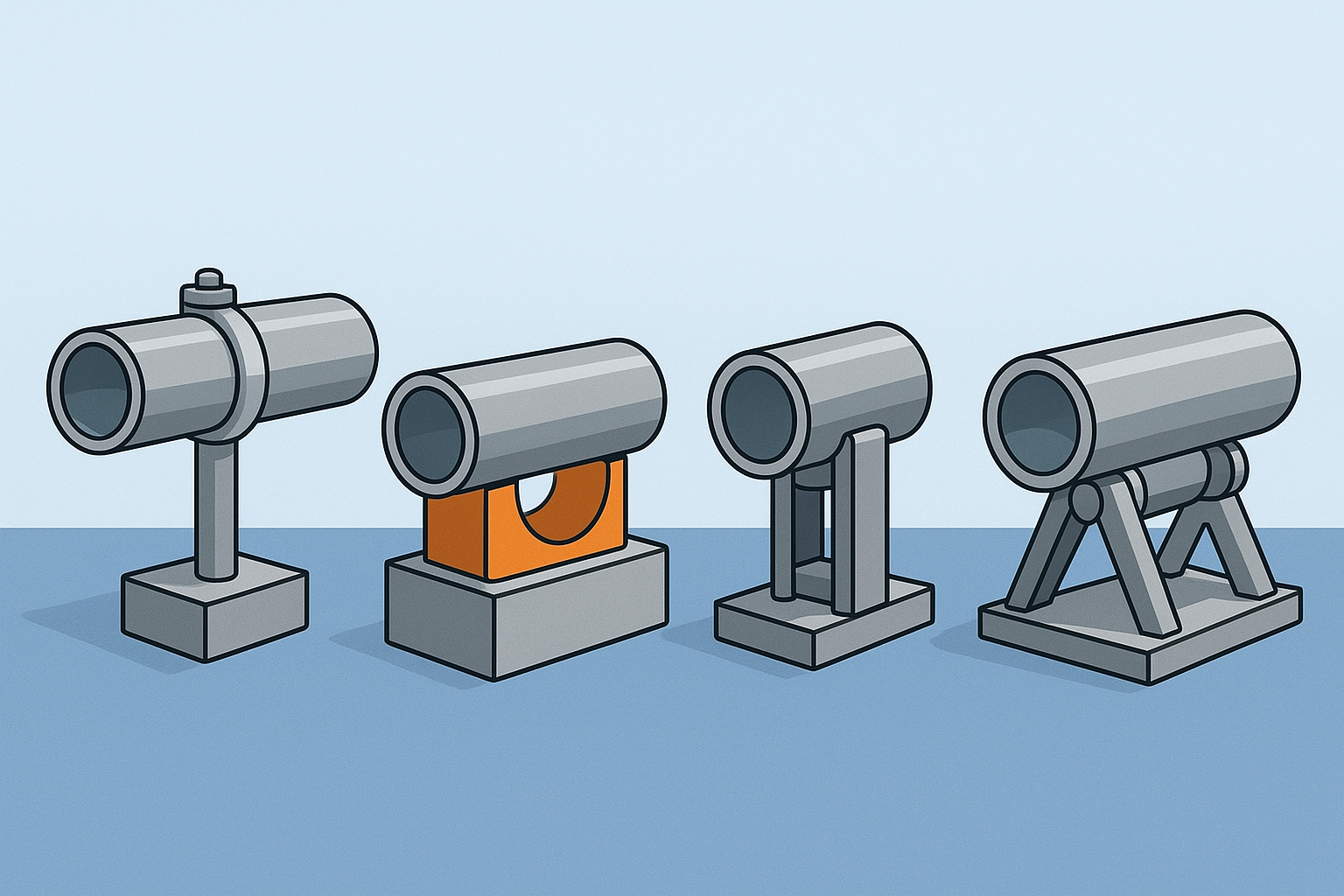

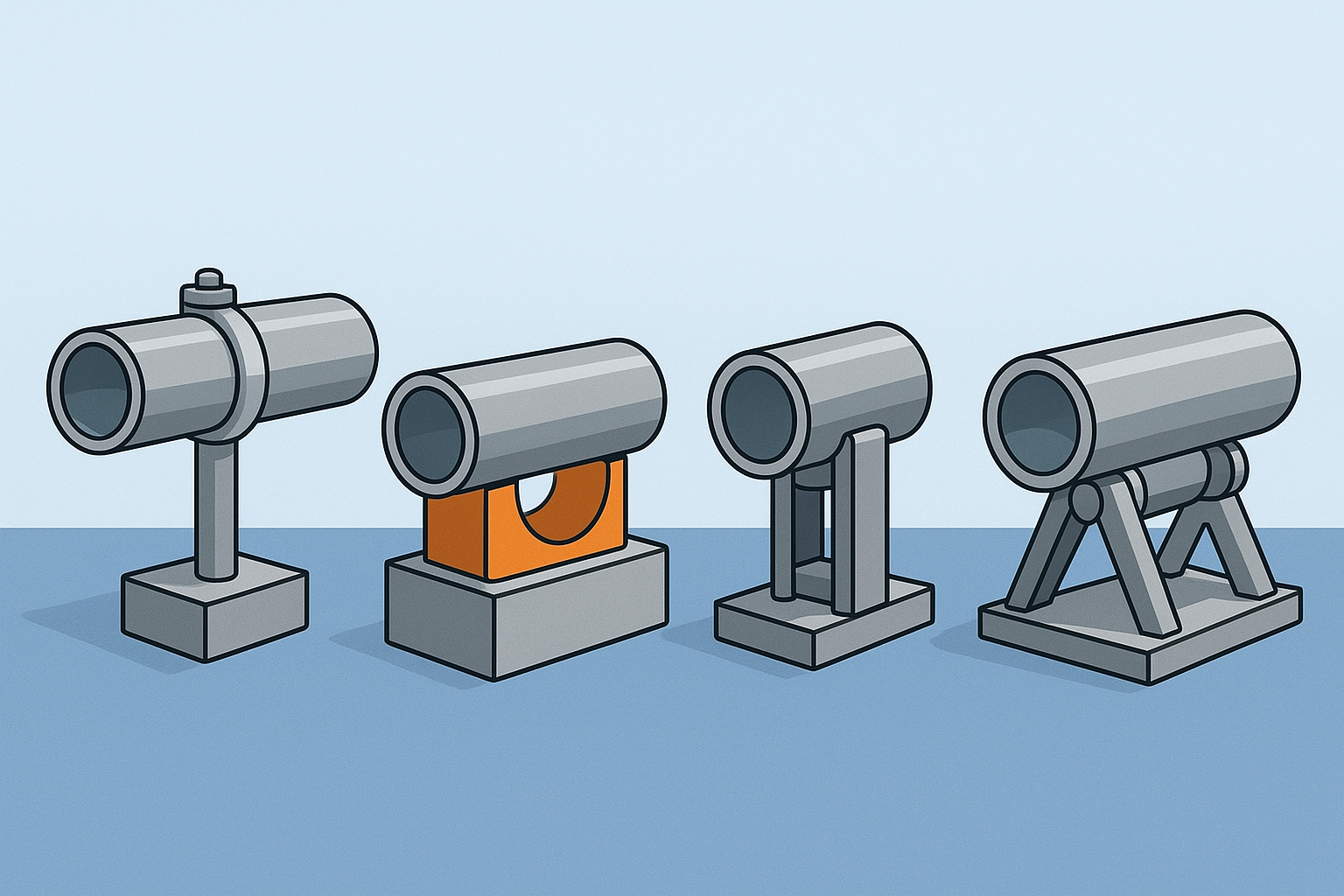

Pipe supports are vital to preserving the integrity, stability, and safety of pipe systems. A well-designed support system provides load distribution, vibration reduction, thermal expansion management, and equipment protection. Here are some of the most frequently...