Our Blogs

Latest Articles

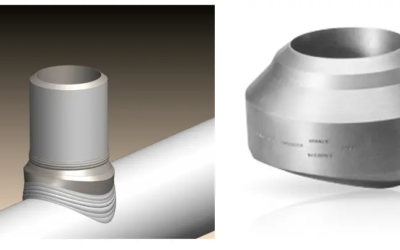

What is the difference between Sockolet and Weldolet?

A Sockolet is identical to a Weldolet, except that the branch pipe is joined to the run pipe via the fitting using a socket weld connection. Instead of using branch pipe types such as the reducer,...

Carbon Steel Properties

carbon steel properties

Benefits of using Seamless Pipes and Tubes in Industrial applications

Seamless pipes are vital components in many industries due to their longevity, strength, and versatility. Seamless pipes have shown to be the best choice for a wide range of industries, including...

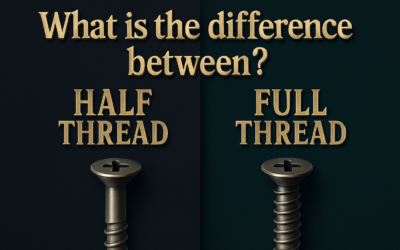

What is the difference between half thread and full thread?

Threads are an important component of fasteners and piping components because they determine their strength and suitability for various applications and usage situations. To ensure optimal project...

How to remove rust from stainless steel

Stainless steel is a popular, durable surface for kitchens that resists rust and stains. If the protective chromium film on your appliances, pots, or sink is destroyed, they will start to...

Steel in Service: Building the Foundation of National Defense

steel in defence