by user | Jun 28, 2025 | Blog

Steel is one of the most commonly used and necessary metals for humanity. Many products in your home contain steel. Carbon steel stands out from other forms of steel due to its unique qualities, which make it highly valuable in a variety of industries. Carbon...

by user | Jun 24, 2025 | Blog

Seamless pipes are vital components in many industries due to their longevity, strength, and versatility. Seamless pipes have shown to be the best choice for a wide range of industries, including oil and gas, construction, and chemical processing. This blog examines...

by user | Jun 8, 2025 | Blog

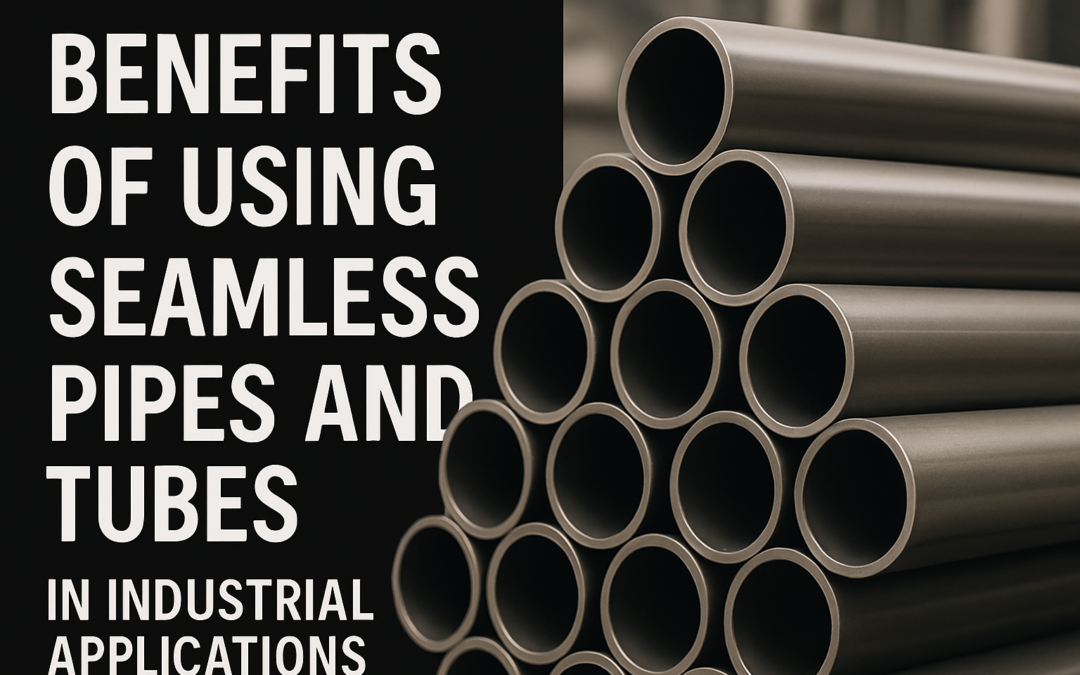

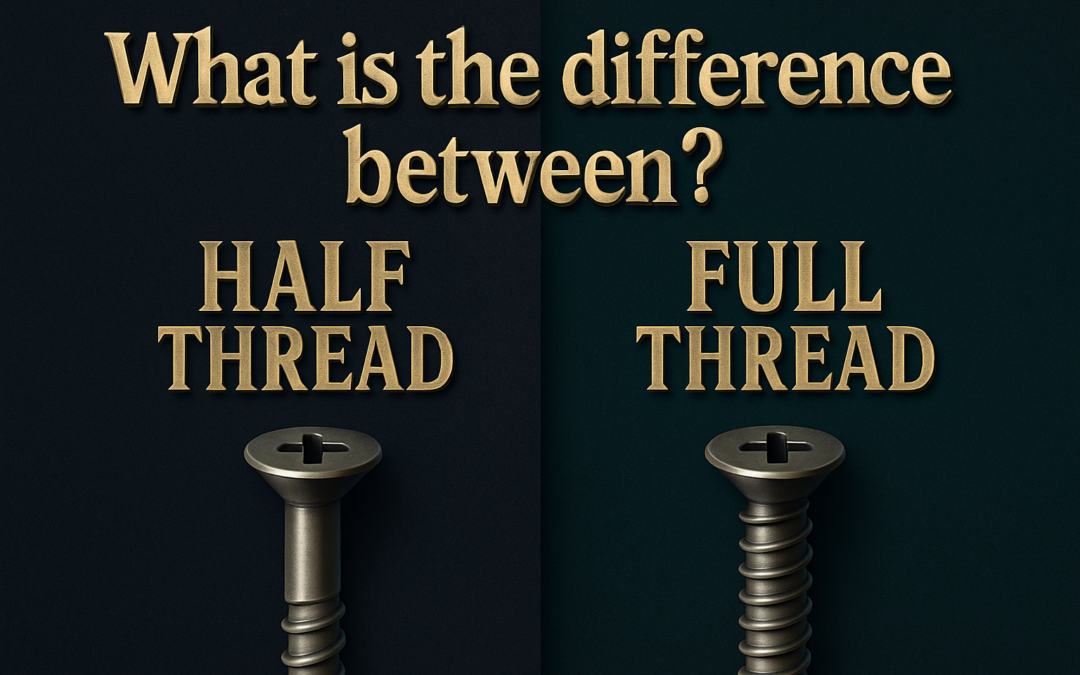

Threads are an important component of fasteners and piping components because they determine their strength and suitability for various applications and usage situations. To ensure optimal project performance, selecting threaded components necessitates understanding...

by user | May 29, 2025 | Blog

Stainless steel is a popular, durable surface for kitchens that resists rust and stains. If the protective chromium film on your appliances, pots, or sink is destroyed, they will start to rust. It is critical that you understand how to remove rust and...

by user | May 10, 2025 | Blog

Steel, a material associated with strength and durability, is used extensively in national security and military applications. Its excellent qualities make it an important component in a variety of military technology, including armored vehicles, naval vessels,...