When sealing raised or flat face flanges, there are two gasket shapes available: ring-type and full-face. Each has advantages, so you should choose which is ideal for your application before ordering and installing. First, let’s look at the many sorts of flanges where gaskets are fitted.

Flange Faces

Various types of flange faces are used as the contact surface for sealing gasket materials. ASME B16.5 and B16.47 describe numerous types of flange facings, such as the raised face, large male, and female facings with identical dimensions to give a relatively large contact surface.

Raised Face (RF) Flanges

The most prevalent type of flange utilized in process plant applications is raised face, which is immediately identifiable. It is known as a raised face because the gasket surfaces are elevated above the bolting circular face. This face type provides for a diverse range of gasket designs, including flat ring sheet types and metallic composites such spiral wound and double jacketed kinds.

The goal of an RF flange is to concentrate greater pressure on a smaller gasket area, increasing the joint’s pressure containment capability. ASME B16.5 defines diameter and height in terms of pressure class and diameter. The pressure rating of the flange controls the height of the elevated face.

Flat Face (FF) Flanges

The gasket surface on the Flat Face flange is in the same plane as the bolting circle face. Flat face flanges are commonly used in applications that need a casting for the mating flange or flanged fitting.

Flat face flanges should never be bolted to a raised face flange. When connecting flat face cast iron flanges to carbon steel flanges, ASME B31.1 requires that the raised face on the carbon steel flange be removed and a full face gasket be used. This prevents the thin, brittle cast iron flange from being pushed into the space created by the elevated face of the carbon steel flange.

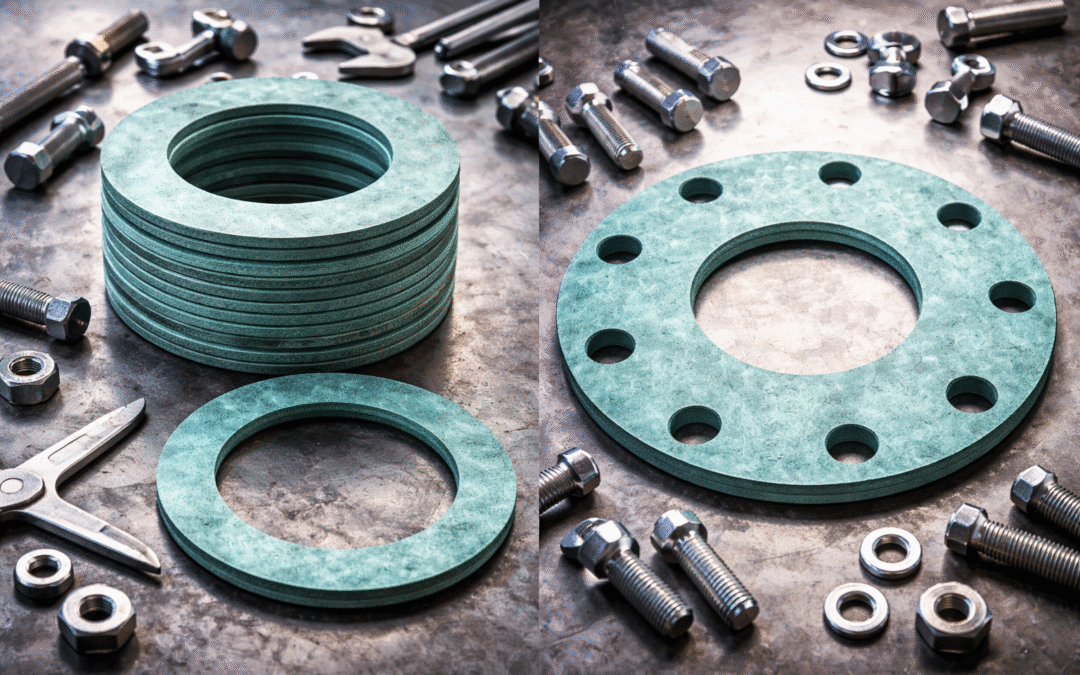

Ring-Type Gasket

This is located inside the flange bolts and surrounding the pipe bore. In a raised face design, it rests on the elevated surface. This design uses less material and cuts less, can be placed without entirely disassembling the joint (making it a “drop-in” gasket), but it can be more difficult to clamp in place.

When providing a ring type gasket, just three specifications are required: ID (the pipe bore), OD (the same as the OD of the raised face), and gasket thickness.

Full-Face Gasket

This, like the ring-type gasket, may seal raised flange faces, but its outer diameter is the same as the flange’s. That means it requires holes for the securing bolts to slide through, which help locate the gasket on the flange and facilitate alignment. Extending out to the flange OD offers the extra benefit of sealing the gap between bolting surfaces, preventing dirt from entering. However, the joint must be entirely disassembled before installation.

A full-face gasket must be specified with the ID (same as the pipe bore), OD (same as the flange OD), bolt circle diameter (the diameter on which all bolt hole centers are located), number of bolt holes (and spacing if they are not regular – which would be very unusual for a flange), and gasket thickness.

If you have any more queries about when to utilize a ring-type gasket or a full-face gasket, our Engineering Department is always available to answer them. Please do not hesitate to contact Newzel Industries for assistance in determining which gasket is ideal for your unique application.