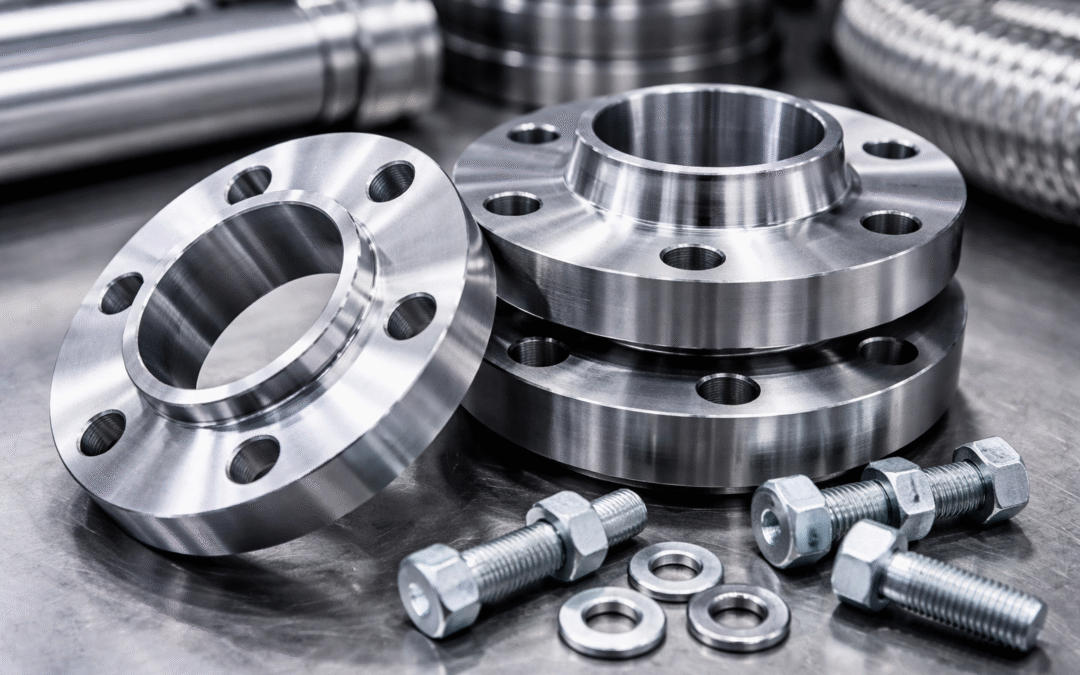

Slip-on flanges, also known as ‘hubbed flanges’, include a low-profile hub. This sort of flange is often attached to a pipe with one or two fillet welds (one outside and one inside the flange), however it is possible to utilize only one weld. Slip-on flanges are available in several diameters and are ideal for lower pressure applications (ASME class < 600).

A slip-on flange has a bigger bore (internal diameter) than the connected pipe, allowing it to slide/slip onto the pipe. There is no full penetration weld between the pipe and the flange, hence its use is limited due to poor weld integrity.

If a welding neck flange cannot be utilized owing to space constraints, a slip-on flange may be a viable option.

The benefits of slip-on flanges include lower procurement costs, less necessary skill for welding, lower accuracy requirements for pipe cutting, and no weld preparation needs for a pipe end weld.

Limitations for slip-on flanges relate to:

The use of two welds rather than one (typically).

Reduced mechanical strength (the welding neck flanges are 30% stronger).

Unsuitable for cyclical loads.

Inability to conduct some non-destructive testing on welds.

In ASME class 1500, sizes larger than 2.5 inches are not available.

ASME class 2500 does not offer all sizes.

Generally not utilized above ASME class 600.

Although cheaper than a welding neck flange, there is minimal cost difference between two welds, and both must be examined using non-destructive testing techniques.

Non-Destructive Testing (NDT) Techniques

There are no specific NDT techniques for slip-on flanges. A dye penetrant test can be performed on a slip-on flange that has been fillet welded. Visual inspection of the mating faces and pipe is available.

ASME Standards

ASME B16.5 and ASME B31.3 define the requirements for slip-on flange installation, maintenance, and testing.