In reality, leak prevention is frequently centered on gaskets, flanged joints, and pipe material selection.

This attention is necessary, but not sufficient.

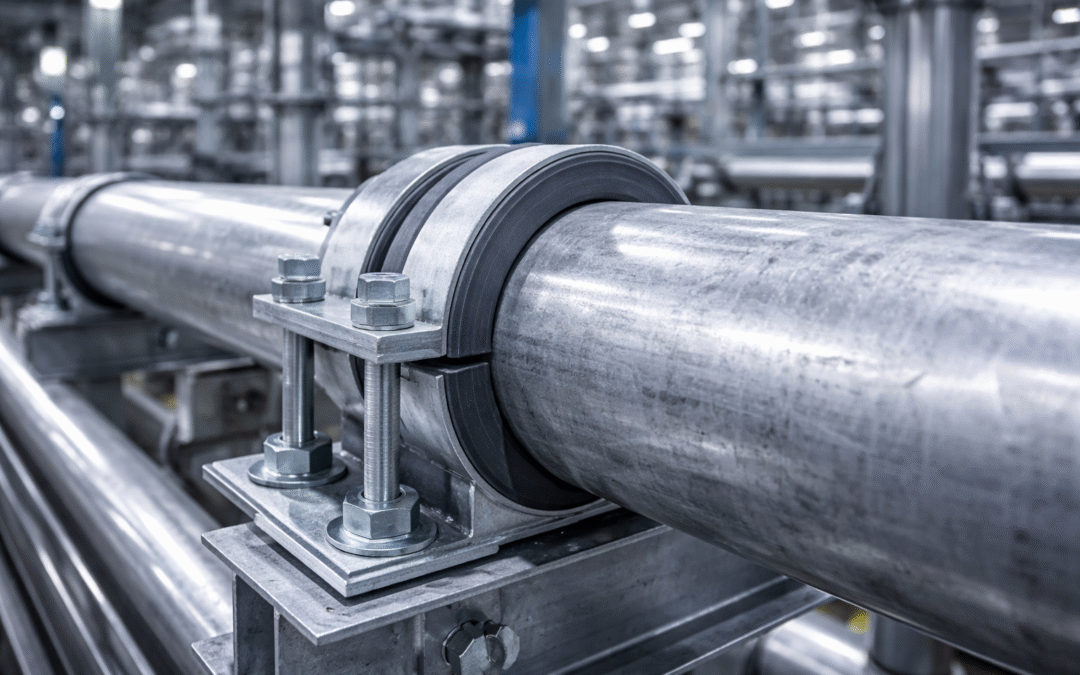

From an asset integrity standpoint, the interface between pipe and pipe support is a systemic influencing factor that, if not effectively addressed, can contribute to long-term damage development.

Pipe supports do more than just hold loads.

In operating circumstances, they influence:

local stress distribution

relative movement due to thermal expansion

Expansion

coating integrity

moisture accumulation at the contact interface

local stress distribution

relative movement due to thermal expansion

Expansion

coating integrity

moisture accumulation at the contact interface

If these consequences are not properly addressed, degradation mechanisms such as:

fretting and abrasion

coating failure

vibration-induced damage

corrosion under supports (CUS)

In many damage scenarios, the support area is not the primary source of the leak, but it does serve as a significant damage accelerator.

The choice and design of appropriate interface solutions

Wear pads, elastomeric or composite interfaces, and coated bearing surfaces should be considered as part of a comprehensive leak prevention and integrity plan, rather than as a solo solution.

Leak prevention does not start in a single location. Consistent engineering decisions during design, operation, and maintenance lead to this outcome.