Introduction

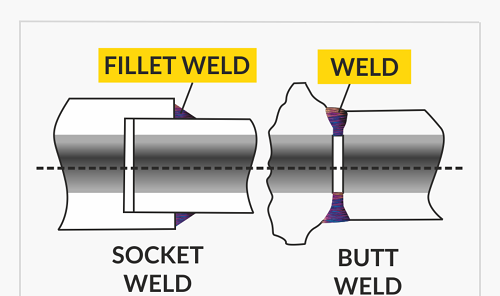

Because there are variances between socket weld and butt weld fittings, the applicable standards are different.

Socket welds entail inserting the pipe into a depression at the joint, with no need to bevel the pipe ends or prepare the materials except to ensure they are clean.

Butt welds demand that the fittings have the same thickness as the pipes. Butt-welded joints must also have beveled ends.

In addition to practical differences, butt weld fittings have a higher strength. Socket weld fittings are typically reserved for pipelines with relatively small diameters. Because of this strength differential, butt welds are preferable for high temperature and pressure applications, as well as where the weld joint strength does not need to exceed that of the base metal.

Is a socket weld the same as a fillet weld?

A socket weld differs from a fillet weld, despite certain similarities in design.

How do you install a socket weld?

To install a socket weld, put a pipe into the fitting’s recess, leaving at least a 1/16″ space to allow for thermal expansion of the pipe under welding pressure. Once the pipe is in place, it can be secured with a series of fillet-type welds. The thermal expansion gap protects the weld from cracking if the pipe expands against the fitting.

What is a Socket Weld Flange?

Socket weld flanges are typically utilized on smaller diameter, high-pressure pipelines. The pipes are placed into the socket end and held in place by fillet-style welds around the top.

Can you radiograph socket welds?

Socket welds can be radiographed; while this is not the best approach for judging weld quality, it will tell you if the root gap is appropriate.

Why use socket weld fittings?

Socket weld fittings connect lines of small diameter pipe used to transport flammable, hazardous, or expensive products that cannot leak. Socket weld fittings are also suitable for steam at a pressure of 300-600 psi. They can form a high-strength union with a high flow rate and a lower risk of leakage.

Conclusion

Socket welding connects pipes with a variety of fittings, allowing for changes in the direction and diameter of pipe networks as well as the creation of branches from existing pipelines.

Socket weld fittings, which are mostly used for smaller pipes, provide leak-proof joints that can sustain high pressures while maintaining high flow characteristics. The fittings are available in a variety of styles and materials to meet a variety of needs.